Application of The Screening Equipment GTC Trommel Screen

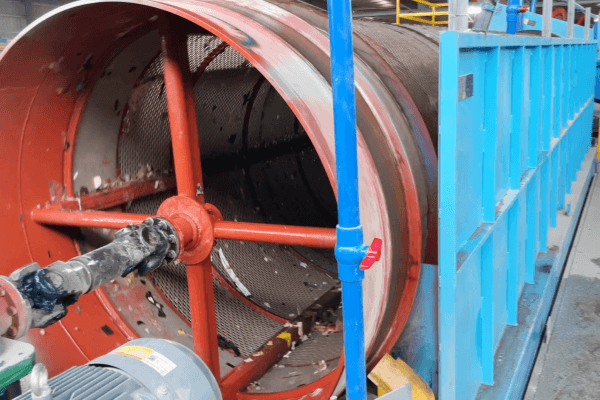

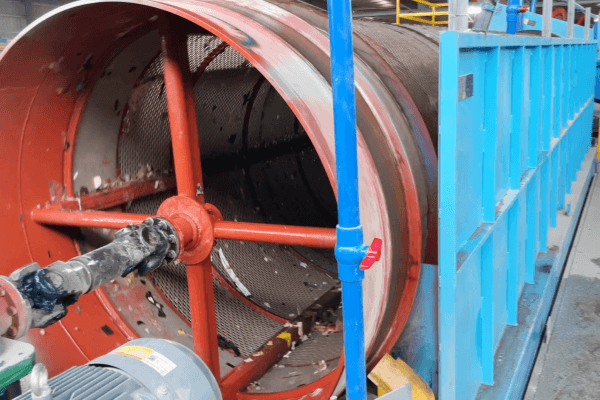

The GTC trommel screen delivers reliable classification and separation across a wide range of industrial scenarios:

Mineral Processing: Grades large and small ore lumps, and separates fine powdery materials to optimize downstream beneficiation.

Stone Yards & Aggregate Production: Sorts large and small stones, and separates soil, stone powder, and gravel for construction material production.

Coal Industry: Classifies coal by particle size to meet combustion efficiency requirements for power plants and industrial boilers.

Building Materials & Recycling: Processes recycled construction waste and aggregates to produce graded materials for new infrastructure projects.

Features of The Screening Equipment GTC Trommel Screen

Operator-Friendly Design Design

Simple structure with intuitive controls, enabling quick operation and easy maintenance to reduce labor costs.

Low Blockage & Long Lifespan

Optimized drum and sieve design minimizes material clogging, while durable construction ensures extended service life with fewer replacements.

Flexible Enclosure Options

Available in fully enclosed and semi-enclosed configurations to suit dust control and site environment requirements.

Customizable Aperture Sizes

Tailored sieve hole dimensions for precise classification of different material types and particle size needs.

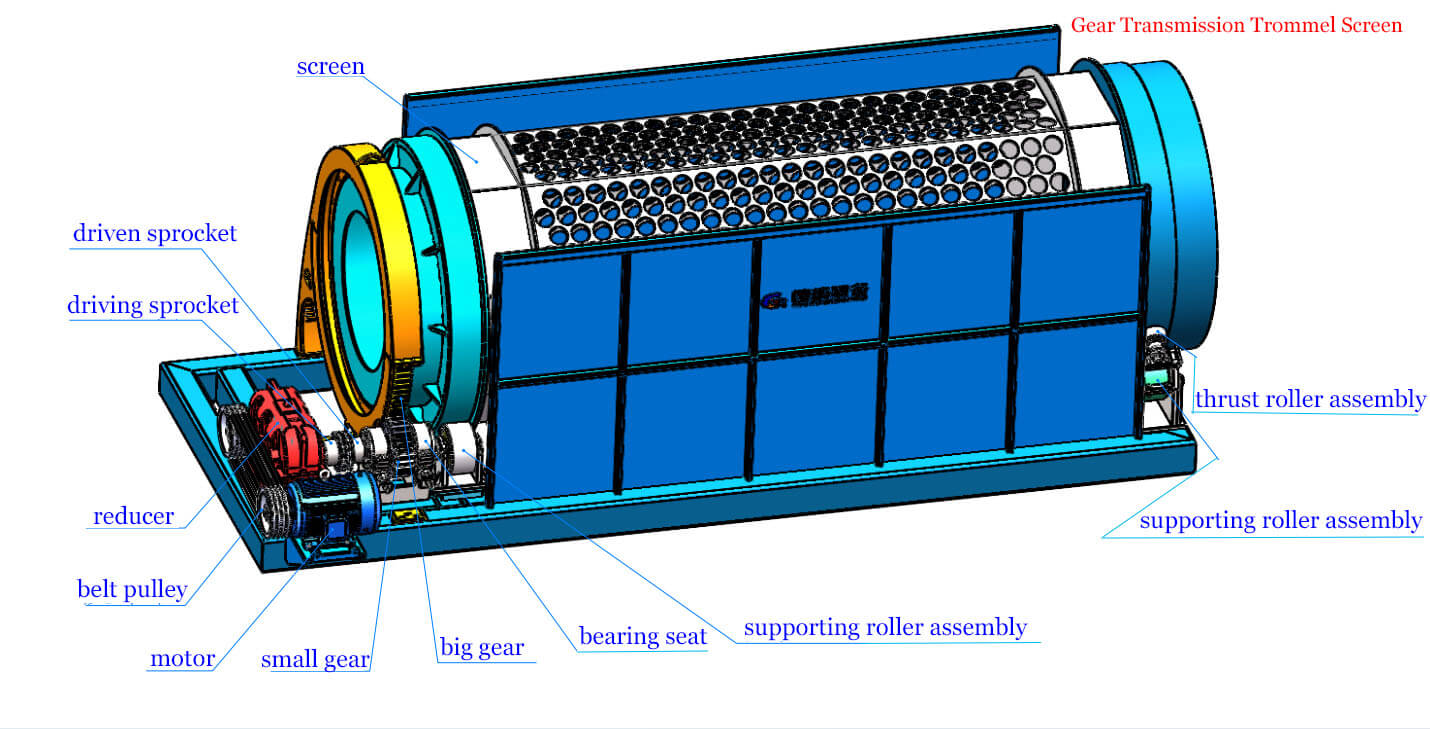

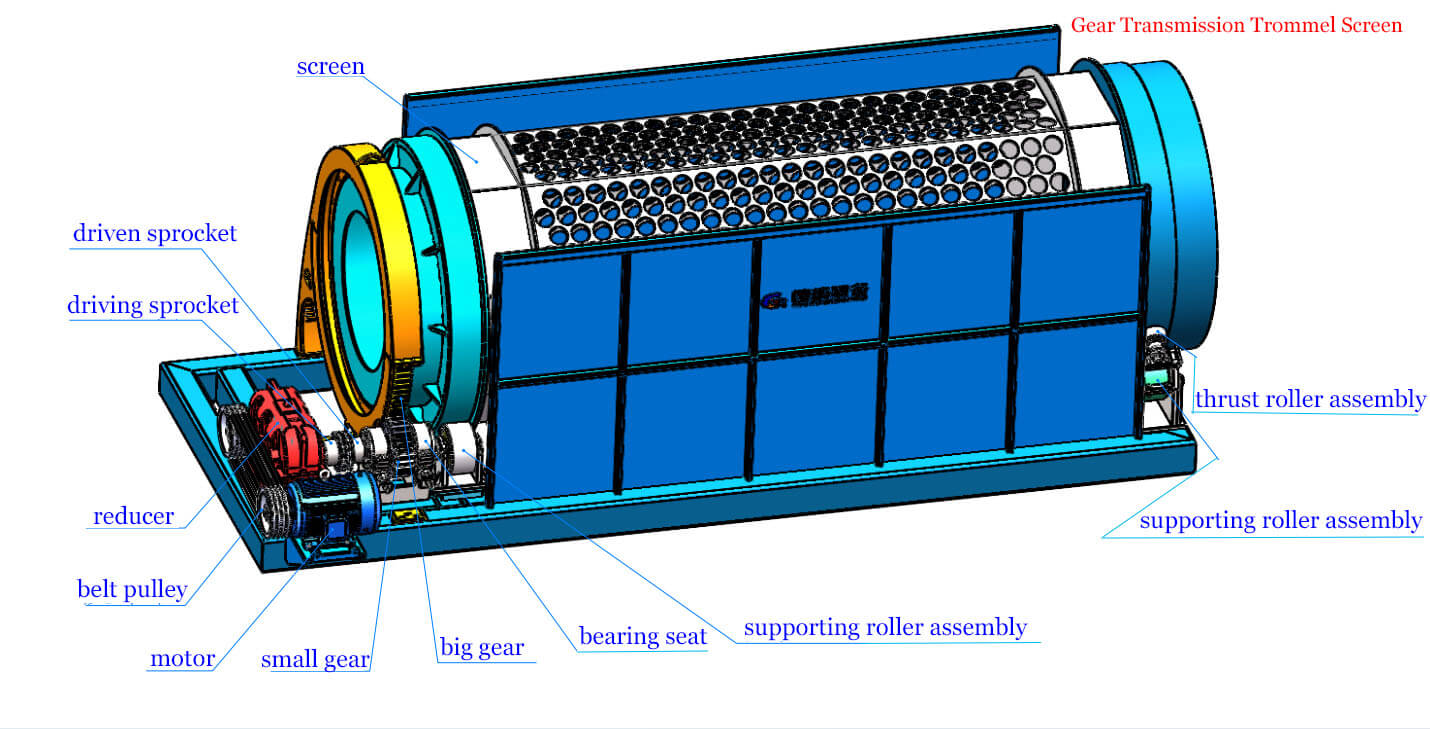

Structure of The Screening Equipment GTC Trommel Screen

This screening machine GTC trommel screen consists of screen, reducer, belt pulley, gear, motor, supporting roller assembly, etc.

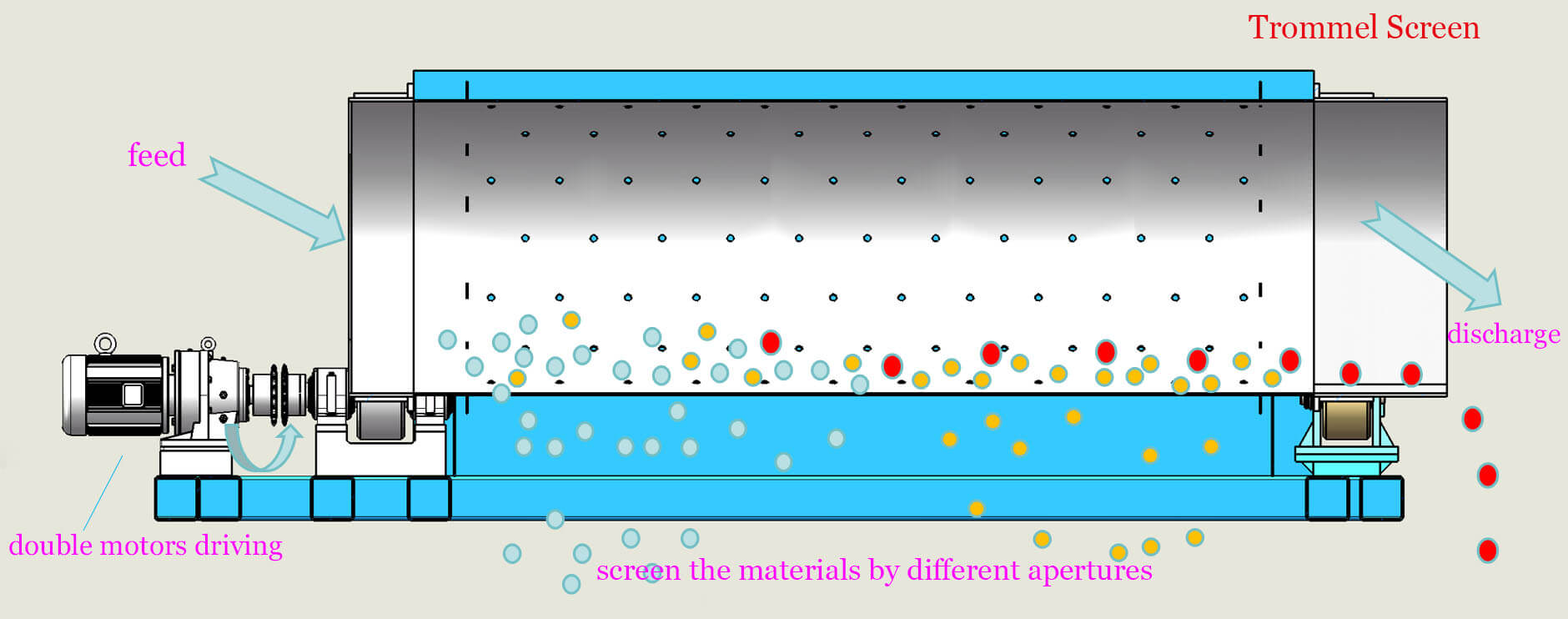

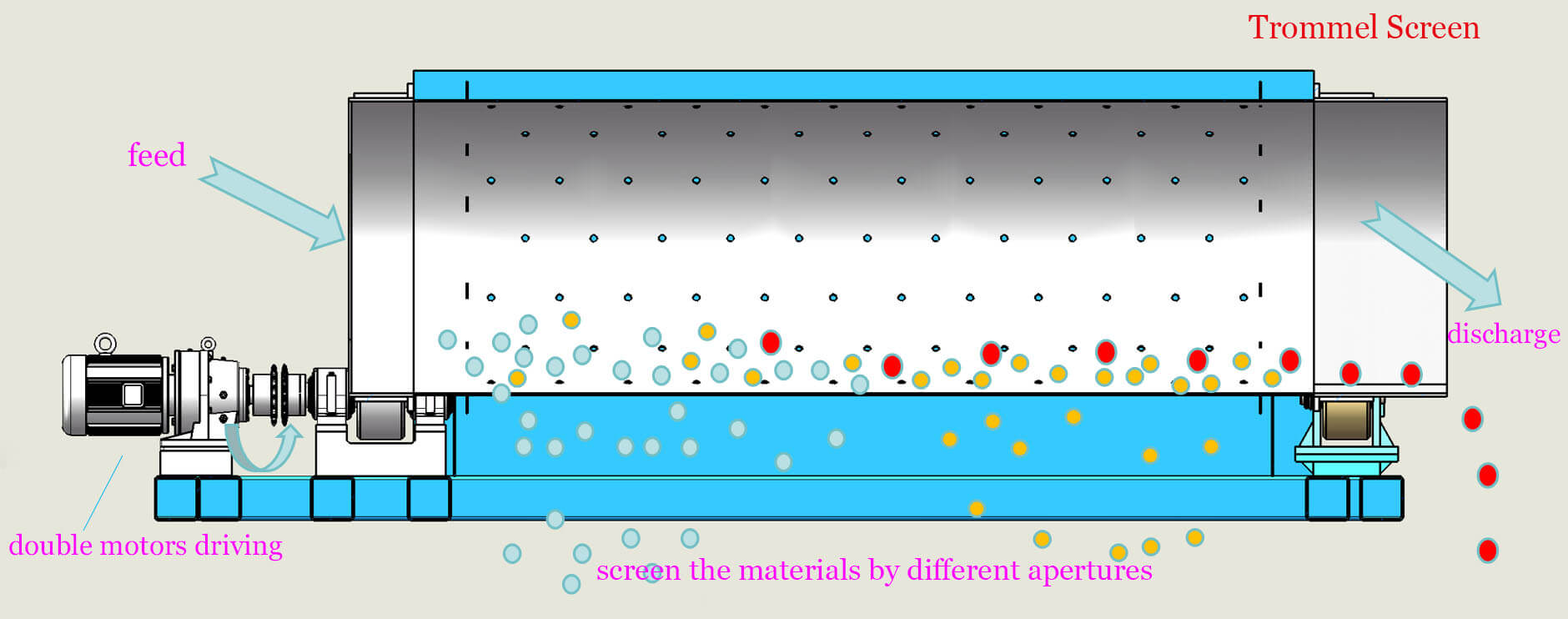

Working Principle The Screening Equipment GTC Trommel Screen

When there are materials entering the drum of the screening machine, the machine keeps turning and rolling process, then the materials passing through different apertures, those diameters are smaller that the apertures will be discharged from the sieve holes, while those larger will be discharged from the discharge port at the tail of the drum. (the apertures size can be customized according to customer requirements)

More Models of The Screening Equipment GTC Trommel Screen

| Model | Power (kw) | Cylinder Rotation Speed (r/min) | Maximum Feed Particle Size (mm) | Processing Capacity (t/h) | Weight(kg) | Dimension(L*W*H)(mm) |

| GTC0818A | 3 | 24 | Mesh Size*2.5 | 2-10 | 1555 | 2895*1300*1120 |

| GTC1248 | 7.5 | 22 | Mesh Size*2.5 | 20-50 | 4396 | 6537*1850*1710 |

| GTC1255 | 7.5 | 22 | Mesh Size*2.5 | 22-52 | 4916 | 7700*1850*1904 |

| GTC1360 | 11 | 22 | Mesh Size*2.5 | 25-60 | 4553 | 7687*1900*1710 |

| GT1556 | 15 | 19 | Mesh Size*2.5 | 30-70 | 5326 | 7923*2050*2130 |

This Gear Transmission Trommel Screen can be customized according to specific application, for example, for dry separation, for iron separation, for the floating removal, and so son.