Application

Eddy current separator is one of the newly specialized machines in the areas of recycling solid wastes. This development aims at better metal recovery from solid wastes and discovering as many potential metal resources as possible in domestic and industrial wastes.

Principle

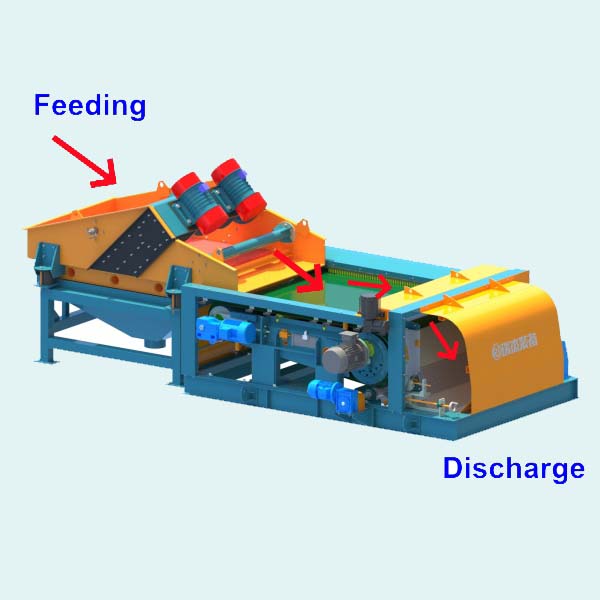

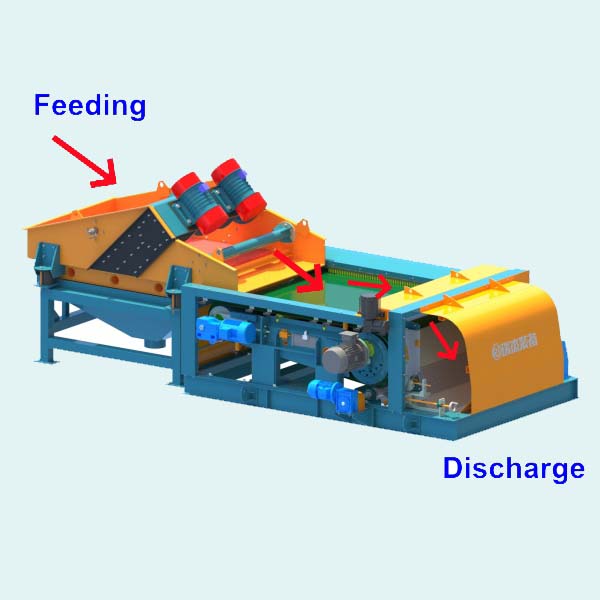

Material is conveyed to a vibrating feeder via a conveyor belt. The feeder’s high-frequency vibration screens moisture from the material and generates forward thrust, propelling the material evenly into the eddy current separator.

When the eddy current separator operates, its magnetic drum rotates rapidly—creating a strong, high-frequency magnetic field on the surface of the sorting drum. As non-ferrous metals (e.g., copper, aluminum) pass through the separator’s magnetic zone, the changing magnetic field induces eddy currents inside the metals.

These eddy currents generate their own magnetic field, which repels the separator’s original magnetic field. This repulsive force pushes the metal pieces forward along the conveyor path, launching them out of the main material stream.

In contrast, non-metallic materials (such as plastics, glass) are unaffected by magnetism and fall straight down. This "magnetic repulsion" effect enables clean separation of metals from other waste.

Feature

●Excellent Design: simple to set up, easy to operate, and quick to maintain.

●Skirted Feeding Belt: Equipped with small dust strips, it helps maintain cleaness and prevents material spillage onto the feeding belt--thus reducing wear on the belt surfave and vortex rotor.

●RunsLong-term Stable Operation: Few malfunctions and a long service life.

●Equiped with Branded Motor: Ensures more stable operation and extends the overall life of the equipment.

Structure

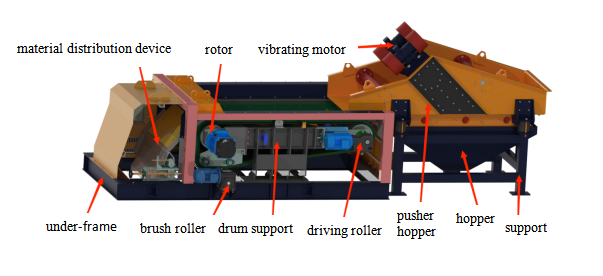

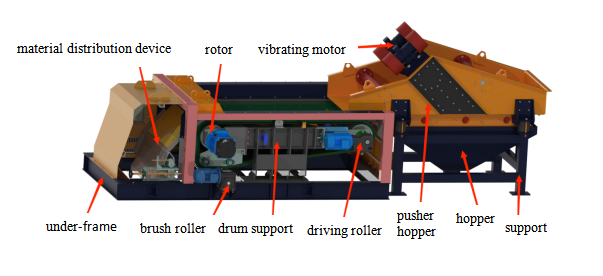

Ruijie Eddy Current Separator is consised of rotor, motor, belt, drum, under-frame, and usually equipped with a vibrating screen for evenly feeding.

Technical Parameter

Model | Dimensions (L*W*H) (mm) | Effective Belt Width(mm)

| Feeder Specification(mm) | Processing Capacity(t/h) |

RJ065AL-R | 3311x1778x1297 | 650 | 1817x923x1666 | 2~8mm,2t/h 8~30mm,4t/h 30~80mm,6.5t/h |

RJ080AL-R | 3311x1982x1297 | 800 | 2240x1140x1839 | 2~8mm,2.5t/h 8~30mm,5t/h 30~80mm,8t/h |

RJ100AL-R | 3311x2186x1306 | 1000 | 2440x1356x1897 | 2~8mm,3.5t/h 8~30mm,6.8t/h 30~80mm,10t/h |

RJ100AL-R2 | 3843x2008x2529 | 1000 | 2593x1356x1903 | 2~8mm,3.5t/h 8~30mm,6.8t/h 30~80mm,10t/h |

RJ150AL-R | 3311x2645x1306 | 1500 | 2593x1816x1929 | 2~8mm,6t/h 8~30mm,12t/h 30~80mm,15t/h |

RJ150AL-R2 | 5209x3089x2664 | 1500 | 2593x1816x3012 | 2~8mm,6t/h 8~30mm,12t/h 30~80mm,15t/h |

RJ200AL-R2 | 5209x3642x2664 | 2000 | 3490x2416x3320 | 2~8mm,7.5t/h

8~30mm,15t/h

30~80mm,18t/h |

Advantages

The industrial eddy current separator is a automatic sorter machine , highly applicable and widely used in Incinerator Bottom Ash(IBA) recovery, aluminium can recycling, and other non-ferrous metal material separation.

It is equiped a cabnet system for antomatic control of the magnetic separarors, and matched a dewatering screen for actual use.

Ruijie user-friendly innovative eddy current separator has a high recovery rate up to 98% and large process capacity. If choose a belt with 65cm effective width, it can process 4 tons raw materials( 8~30mm) per hour.

Ruijie offer different models for selection, also support tailor-made non-ferrous metal processing machine.