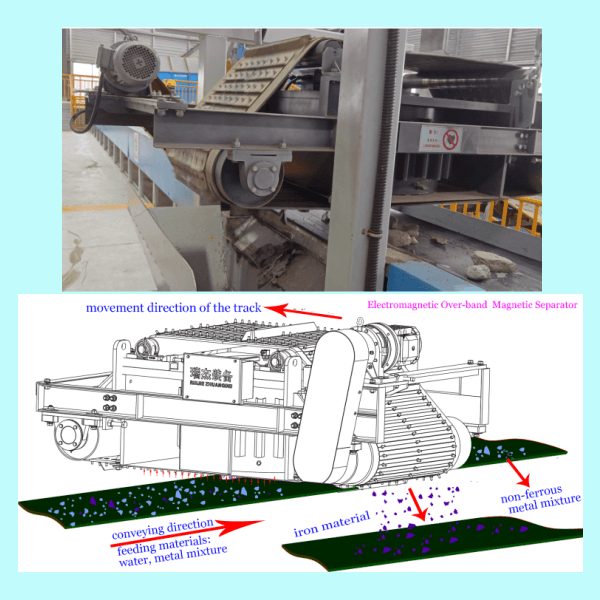

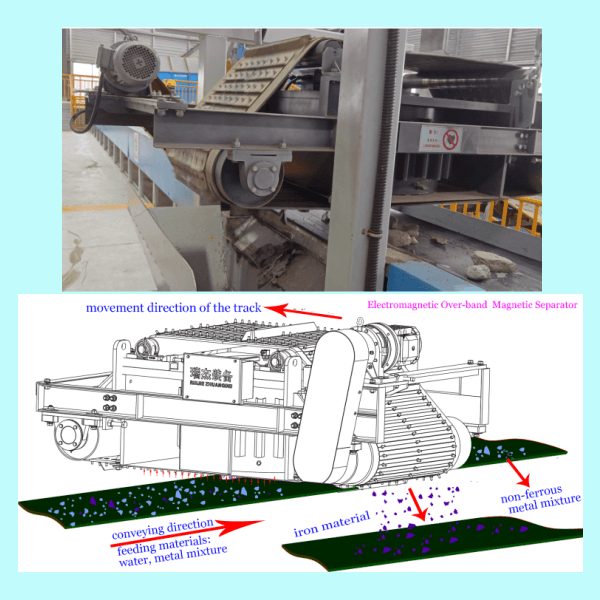

Application

Ruijie electromagnetic over-band magnetic separator creates a high-intensity magnetic field upon activation, efficiently extracting ferrous contaminants from bulk raw materials. Its robust construction integrates a motor reducer, drive roller, track, idler roller, control cabinet, magnetic assembly, and tail roller for reliable continuous operation.

This versatile overband separator is widely deployed across industries, including mineral processing, incineration bottom ash (IBA) recovery, slag treatment, and construction waste recycling, to ensure material purity and protect downstream equipment.

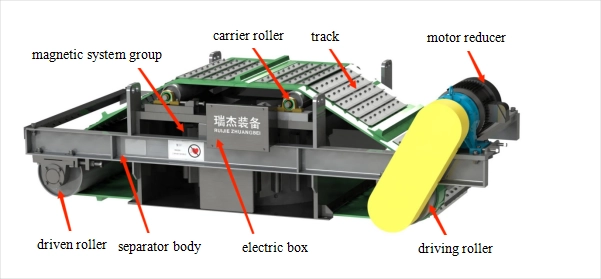

Principle

During operation, the Ruijie electromagnetic over-band magnetic separator generates a high-intensity magnetic field that instantly attracts ferrous contaminants from the passing material stream. The motor reducer drives the conveyor belt system—consisting of tracks, carrier rollers, and drive rollers—to transport the captured ferrous particles to a non-magnetic zone. Once outside the magnetic field, the ferrous materials drop into the dedicated collection bin by gravity, realizing fully automated iron removal with high efficiency.

Feature

●Space-Saving Design: Compact, lightweight, and horizontally installed for seamless integration into existing production lines, enabling efficient ferrous removal with minimal footprint.

●Low Maintenance & Reliability: Optimized structural design ensures easy servicing and long-term, trouble-free operation, reducing downtime and operational costs.

●High Efficiency Separation: Boasts an extended magnetic penetration depth to capture ferrous contaminants effectively, delivering superior separation performance and high productivity.

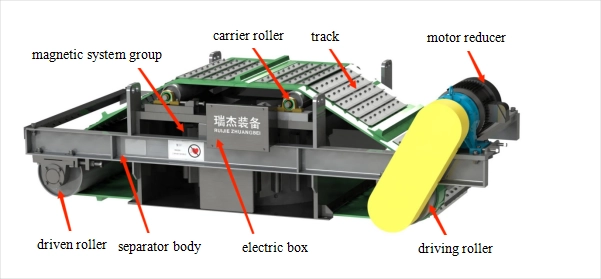

Structure

The Ruijie electromagnetic over-band magnetic separator features a modular, robust design for reliable performance in industrial environments. Its core components include:

Magnetic System Group: Generates a high-intensity magnetic field to capture ferrous contaminants efficiently.

Motor Reducer & Drive System: Consists of a motor reducer, driving roller, and driven roller to power the continuous movement of the conveyor track.

Conveyor Assembly: Includes the track and carrier rollers to transport captured ferrous materials to the non-magnetic discharge zone.

Separator Body: Provides a stable, corrosion-resistant frame that supports all core components.

Control Cabinet (Electric Box): Enables safe, convenient operation and monitoring of the magnetic separator.

Technical Parameter

Model | Effective Track Width (mm) | Conveyor Belt Width (mm) | Roller Rotation Speed (r/min) | Processing Capacity (t/h) | Power(kw) | Dimensions (L*W*H) (mm) | Weight(kg) |

RCDD08 | 599 | ≤600 | 96 | 50-80 | 3.0 | 2554*1346*760 | 1800 |

Installation

Ruijie electromagnetic suspension iron separator can be mounted on the production line via steel wire ropes. Installed at the front end of the line, it is used for the primary screening of large-sized magnetic materials. It can also be deployed at any required stage of the production line to remove small iron impurities.