Application

The permanent magnetic separator integrates key components including a bearing seat, magnetic system group, motor reducer, driving roller, and driven roller. Its robust, adaptable design makes it one of the most widely used solutions for separating magnetic from non-magnetic materials across diverse industrial scenarios.

This equipment is extensively deployed in:

IBA Wet Sorting Processing: Efficiently removing ferrous contaminants from incineration bottom ash (IBA) and steel slag.

Mining & Mineral Processing: Separating ferromagnetic minerals from ore feed.

Construction Waste Recycling: Recovering ferrous metals from mixed construction debris.

Coal Washing Plants: Extracting magnetic impurities to improve coal quality.

Principle

During operation, the permanent magnetic separator generates a stable magnetic field that efficiently adsorbs ferrous particles from material streams on the table concentrator onto its conveyor belt. As the belt moves, it transports the captured ferrous material to a non-magnetic zone, where the iron particles detach automatically due to the absence of magnetic force and fall into the collection hopper, achieving fully automated iron unloading.

Feature

● Compact & User-Friendly Design: Lightweight with an optimized structure, enabling quick installation and easy maintenance for minimal downtime.

● Cost & Labor Efficiency: Automates ferrous separation to reduce manual intervention, cutting labor costs and boosting overall productivity.

● High-Performance Magnetic System: Delivers strong magnetic field intensity and powerful adsorption, with exceptional anti-demagnetization properties for long-term reliability.

● Stable & Quiet Operation: Runs consistently with low noise, ensuring durable performance even under prolonged industrial use.

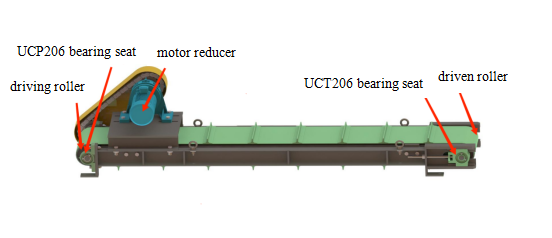

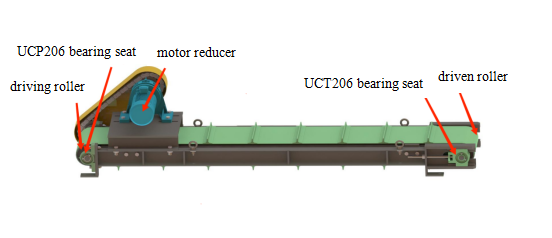

Structure

The permanent magnetic separator features a streamlined, modular design for reliable performance in industrial environments. Its core components include:

Motor Reducer: Delivers stable, adjustable power to drive the conveyor system, ensuring consistent belt speed and separation efficiency.

Driving & Driven Rollers: Work in tandem to support and move the conveyor belt, maintaining smooth material transport.

UCP206 & UCT206 Bearing Seats: Provide robust, low-friction support for the roller shafts, enhancing equipment stability and reducing wear during long-term operation.

This optimized structural layout ensures easy installation, maintenance, and replacement of parts, minimizing downtime and maximizing operational efficiency.

Technical Parameter

Model | Effective Belt Width (mm) | Conveyor Belt Width (mm) | Roller Center Distance (mm) | Reducer Model | Roller Rotation Speed (r/min) | Processing Capacity (t/h) | Power(kw) | Dimensions (L*W*H) (mm) | Weight (kg) |

RCYD3F | 300 | ≤1800 | 2080 | XWD-1.5-3-17 | 85 | 12-18 | 1.5 | 2235*456*566 | 515 |

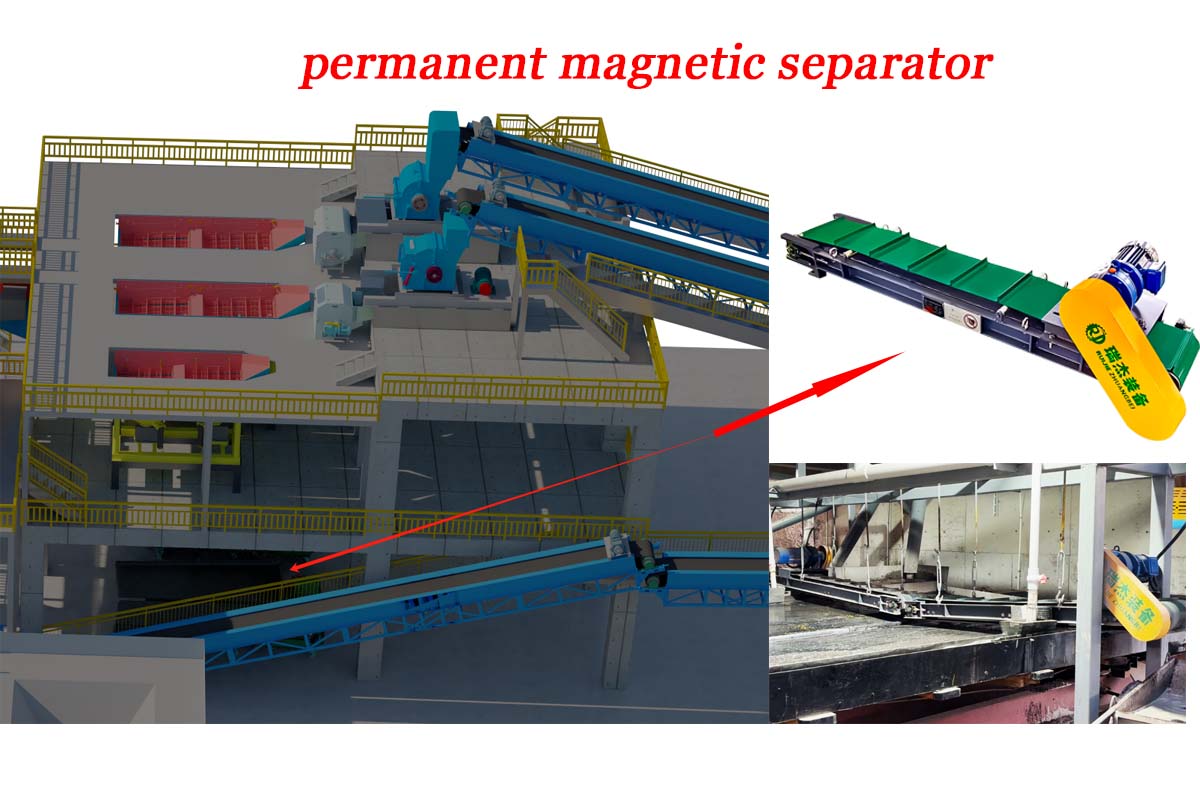

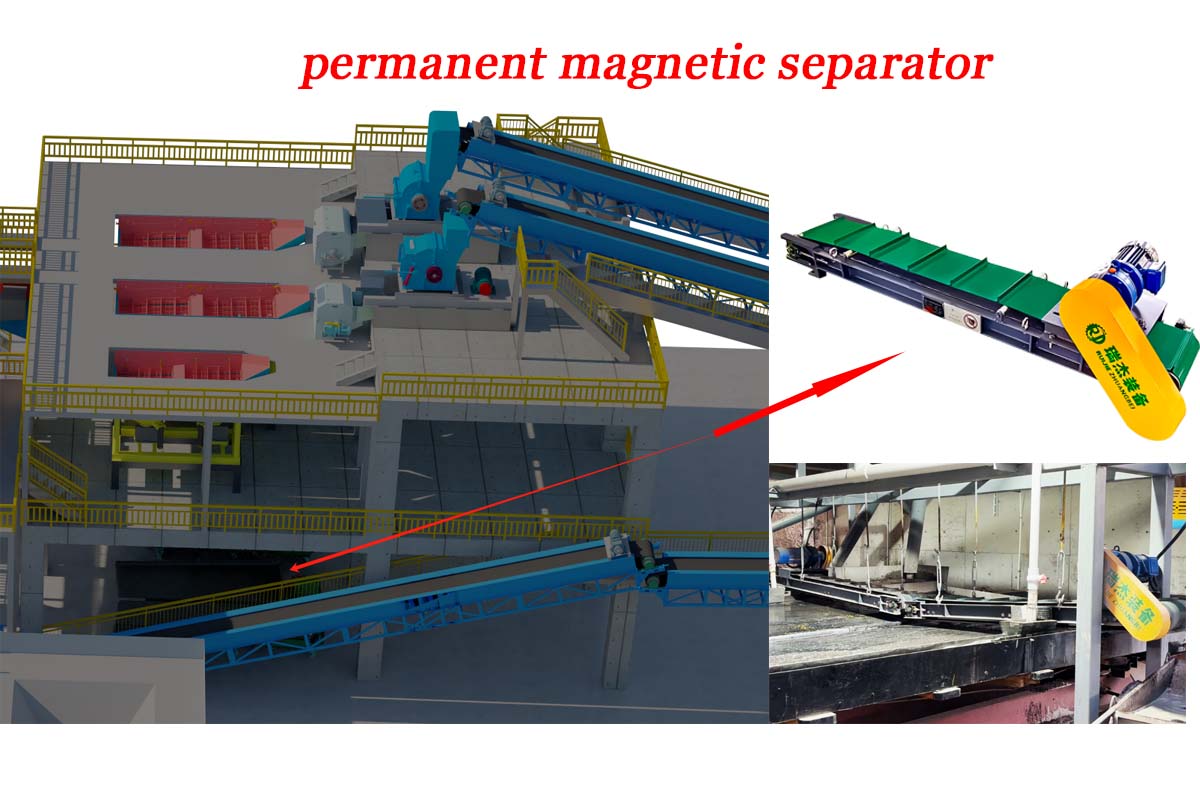

Production Line

The permanent magnetic separator is engineered to efficiently extract fine ferrous particles from mixed material streams. In Incineration Bottom Ash(IBA) wet sorting wet sorting production lines, it is typically installed at the bottom of the processing flow to recover ferrous contaminants from upstream materials, ensuring high-purity separation and resource recycling.