Application

Electromagnetic over-band separator is a type of iron remover that boasts strong magnetism, corrosion resistance, continuous operation capability, and automatic iron discharge—ideal for separating iron impurities from mixed materials.

Widely applied in electric power, mining, building materials, coal, and other industrial sectors.

Principle

When activated, the electromagnetic over-band separator machine generates a strong magnetic field that attracts iron impurities from mixed materials. The adsorbed iron is then transported to a non-magnetic area via the belt track and automatically discharged—achieving efficient iron removal and protecting downstream equipment.

Feature

● Adjustable Magnetic Force: Controlled via electric cabinet for precise, magnetism-loss-free regulation and high sorting cleanliness.

● Flexible Customization: Magnetic strength tweakable by button to match diverse material conditions.

● Stable & Durable: Steady operation, low failure rate, and extended service life.

● Premium Build: Stainless steel key components, precision assembly, waterproof magnetic parts, rust-proof main body.

● Easy Integration: Compact structure for simple installation and seamless addition to various production lines.

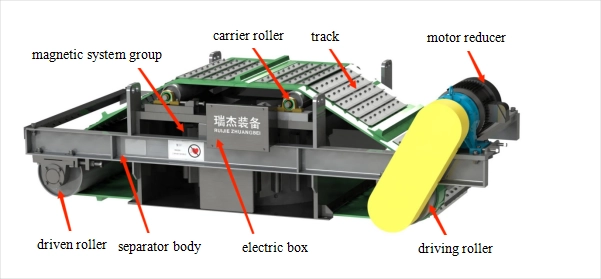

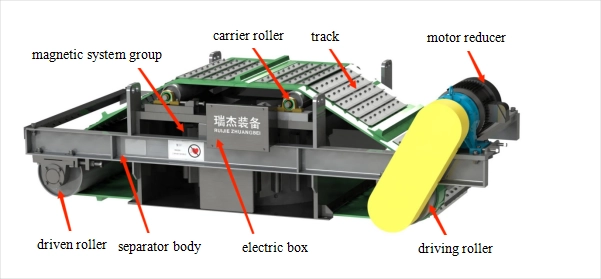

Structure

RUIJIE electromagnetic over-band separator consists of key components:

Magnetic System Group: Core component generating magnetic force

Separator Body: Main frame for structural support

Track & Rollers (Carrier/Driving/Driven): Enable belt operation

Motor Reducer: Power unit for driving the system

Electric Box: Controls magnetic force and equipment operation

Technical Parameter

Model | Effective Track Width (mm) | Conveyor Belt Width (mm) | Roller Rotation Speed (r/min) | Processing Capacity (t/h) | Power(kw) | Dimensions (L*W*H) (mm) | Weight(kg) |

RCDD08 | 704 | ≤800 | 96 | 5 | 3.0 | 2068*1335*968 | 2050 |

Integrated in Production Line

Positioned above the conveyor belt at the front section of IBA wet sorting lines, this industrial overband magnetic separator serves as a critical pre-processing device for iron removal. Its strategic placement leverages the loose material state at the line’s initial stage—ensuring large iron impurities (e.g., metal scraps, iron components) are efficiently captured and separated before materials enter subsequent wet processing steps.

New Style

The electromagnetic can be designed according customer's specific requirements, and its magnetic force can be adjusted and controled by the equipped electric cabinet.