Up-suction Magnetic Separator Application

The up-suction magnetic separator is primarily engineered for ferrous metal recovery from various slag materials, including scrap steel processing, steel slag treatment, and industrial slag sorting, efficiently capturing ferrous particles with a size of less than 5mm. It is also an ideal solution for waste sorting applications, effectively preventing belt damage that commonly occurs with traditional belt-type iron separators. As a cost-effective ferrous separation device, it delivers stable and reliable operation even in the most extreme industrial environments.

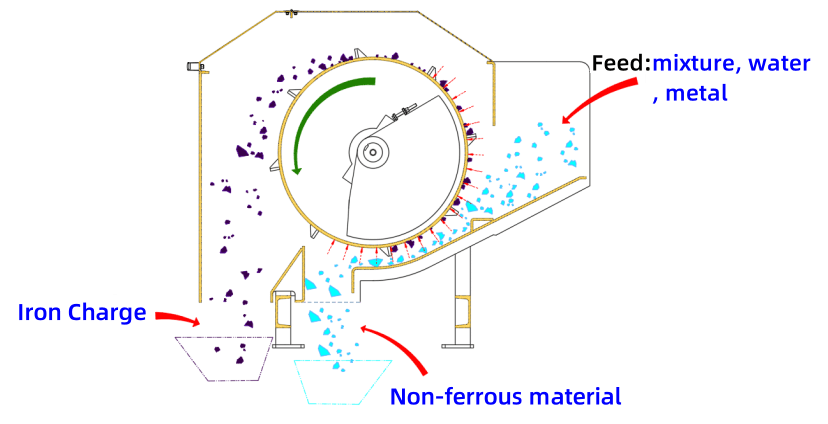

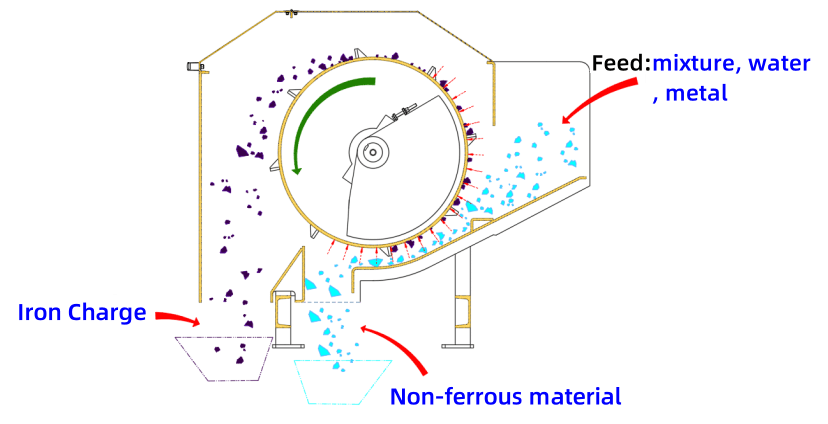

Counterflow Magnetic Separator Principle

As feed material enters the magnetic drum’s working zone, ferrous particles are immediately attracted and adhere firmly to the drum’s surface. The drum’s counterflow rotation then transports these adsorbed particles to a non-magnetic region, where the combined forces of gravity and inertia cause the ferrous material to detach automatically and drop into the dedicated discharge hopper, completing efficient iron separation. The drum’s counterclockwise rotation is specifically engineered to minimize material blockages, ensuring uninterrupted, continuous operation in industrial settings.

Counterflow Magnetic Separator Principle Features

● Low demagnetization rate and high separation purity, ensuring precise ferrous separation results.

● Ferrite magnetic blocks are adopted on the upper part of the magnetic shaft, featuring long magnetic lines, excellent anti-demagnetization performance, and rust resistance.

● The magnetic zone is adjustable up and down to adapt to different material properties and processing requirements.

● Stable operation with low failure rate, contributing to long service life and reduced downtime.

● Rigorous welding and assembly processes, guaranteeing structural stability and reliability.

● Waterproof magnetic shaft design, suitable for humid working environments.

● Main components are made of stainless steel, delivering outstanding wear resistance and rust resistance.

● Compact structure for easy installation, enabling stable operation even in extremely harsh industrial environments.

● Equipped with a top transparent window for convenient real-time observation of the separation process.

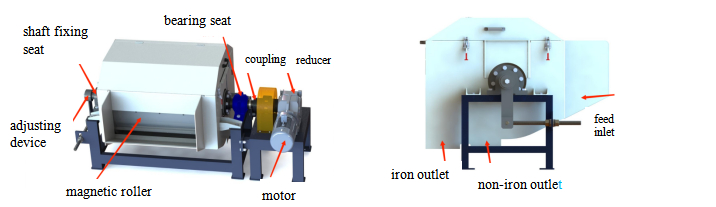

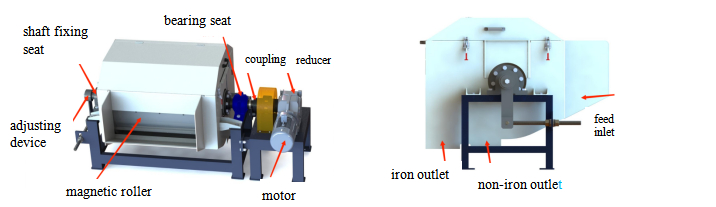

Durable Up-suction Magnetic Separator Structure

The up-suction magnetic separator is built with a robust, corrosion-resistant design to ensure long-term reliability in harsh industrial environments. Its key structural features include:

Core Components

Magnetic Roller: The magnetic drum is constructed from 304 stainless steel, featuring a hermetically sealed design for exceptional rust and corrosion resistance.

Drive System: Consists of a motor, reducer, and coupling to provide stable, continuous power transmission.

Support & Adjustment Mechanism: Includes a shaft fixing seat, bearing seat, and adjusting device for precise alignment and easy maintenance.

Wear-Resistant Parts: Aluminum end caps and stainless steel flanges deliver superior wear resistance, while the stainless steel groove ensures durability.

Optimized Material Flow

The unit is equipped with a dedicated feed inlet, iron outlet, and non-iron outlet, enabling efficient separation and discharge of ferrous and non-ferrous materials.

RUIJIE Up-suction Magnetic Separator Technical Parameter

Model | Roller Diameter (mm) | Roller Rotation Speed(r/min) | Processing Capacity (t/h) | Power(kw) | Weight (L*W*H) (mm) | Weight(kg) |

SX6090R | 600 | 22 | 22-27 | 3.0 | 1946*1246*1255 | 1445 |

Iron Material Separated By the Up-suction Magnetic Sorting Machine

The countercurrent wet-type magnetic separator is engineered for automatic, continuous recovery of heavy medium in coal washing plants, and also efficiently recovers ferromagnetic ores. It integrates a rare-earth NdFeB magnetic system, delivering stronger magnetic force than comparable equipment and achieving an industry-leading media recovery rate of 99.9%.

The images showcase the high-purity ferrous material (left) separated by the machine, alongside the processed non-ferrous residue (right), demonstrating the device’s exceptional separation precision and resource recovery capabilities.

Installation Position in IBA Wet Sorting Production Line

In the (incineration bottom ash) IBA wet sorting production line, the high-efficiency up-suction ferrous metal separation machine is usually installed after the hammer iron cruher, so that to absorb the iron particle from the crushing material, and prevent damage to the subsequent equipment.