Industrial Wet Drum Magnetic Separator Application

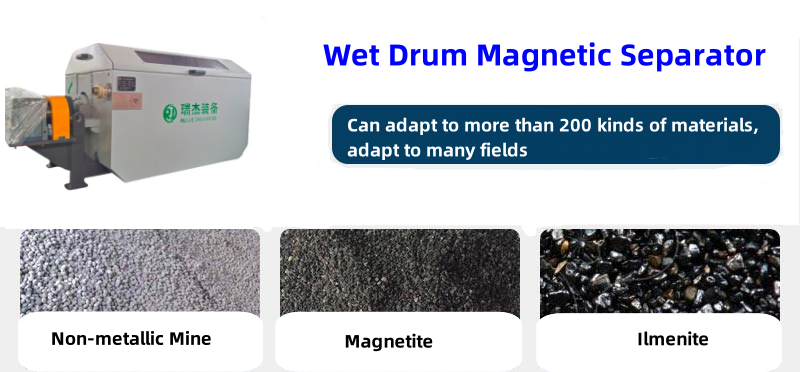

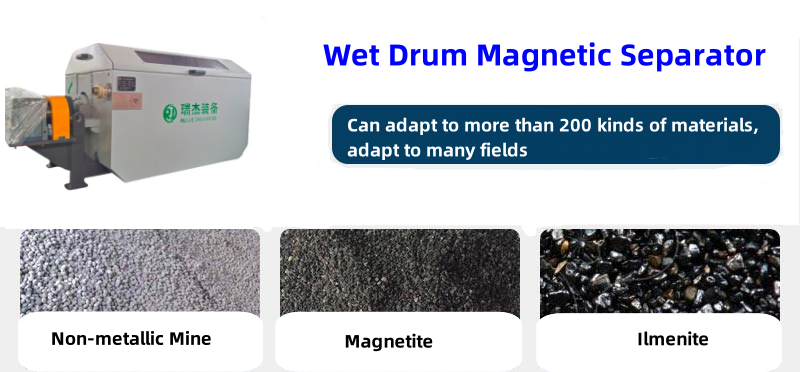

Ruijie wet drum magnetic separator- iron removal equipment, delivers precise iron removal and magnetic material separation across a wide range of industrial scenarios:

Mineral Processing

Separates and enriches weak magnetic ores, including limonite, hematite, and magnetite, as well as processes tailings and sulfuric acid slag to recover valuable metals.

Building Materials & Refractories

Removes iron impurities from quartz sand, potassium feldspar, and refractory materials to enhance product purity and quality.

Mining & Abrasives

Purifies abrasive materials, garnet, and non-metallic minerals by eliminating ferrous contaminants, protecting downstream processing equipment.

Customizable Solutions

Tailored drum size, magnetic intensity, and configuration options to adapt to specific site conditions and material characteristics, ensuring optimal performance for most users.

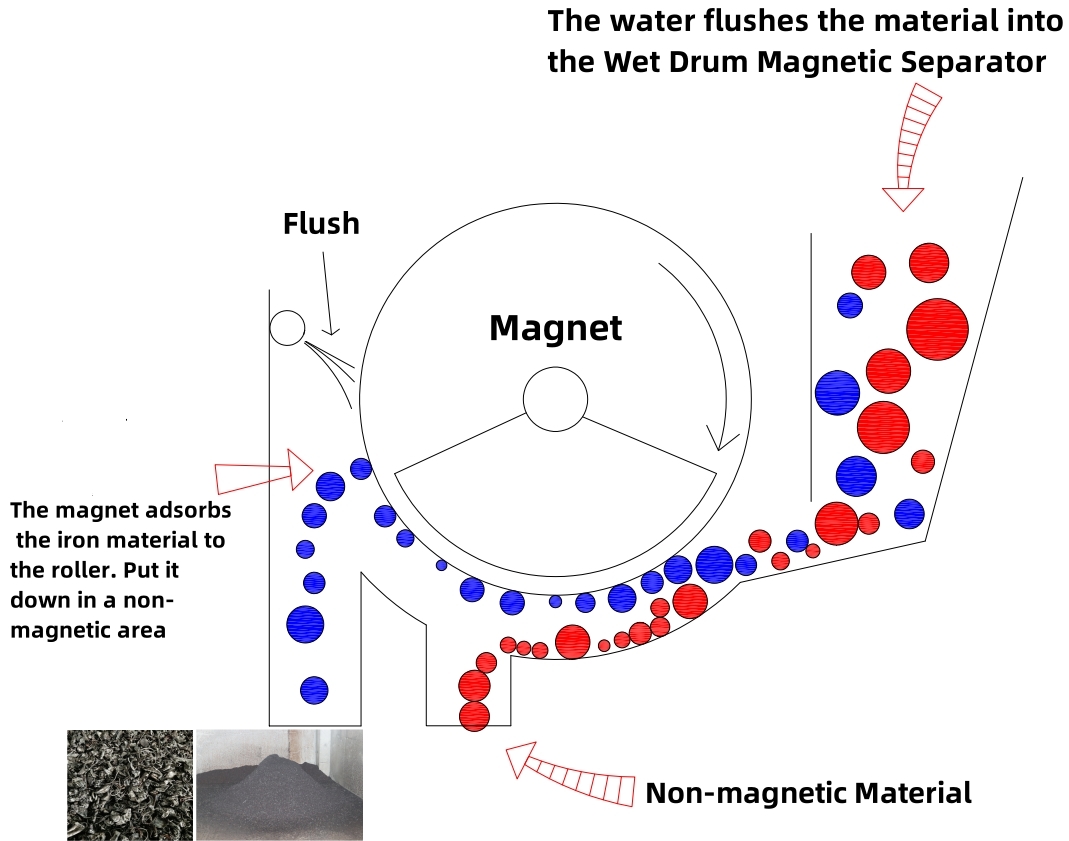

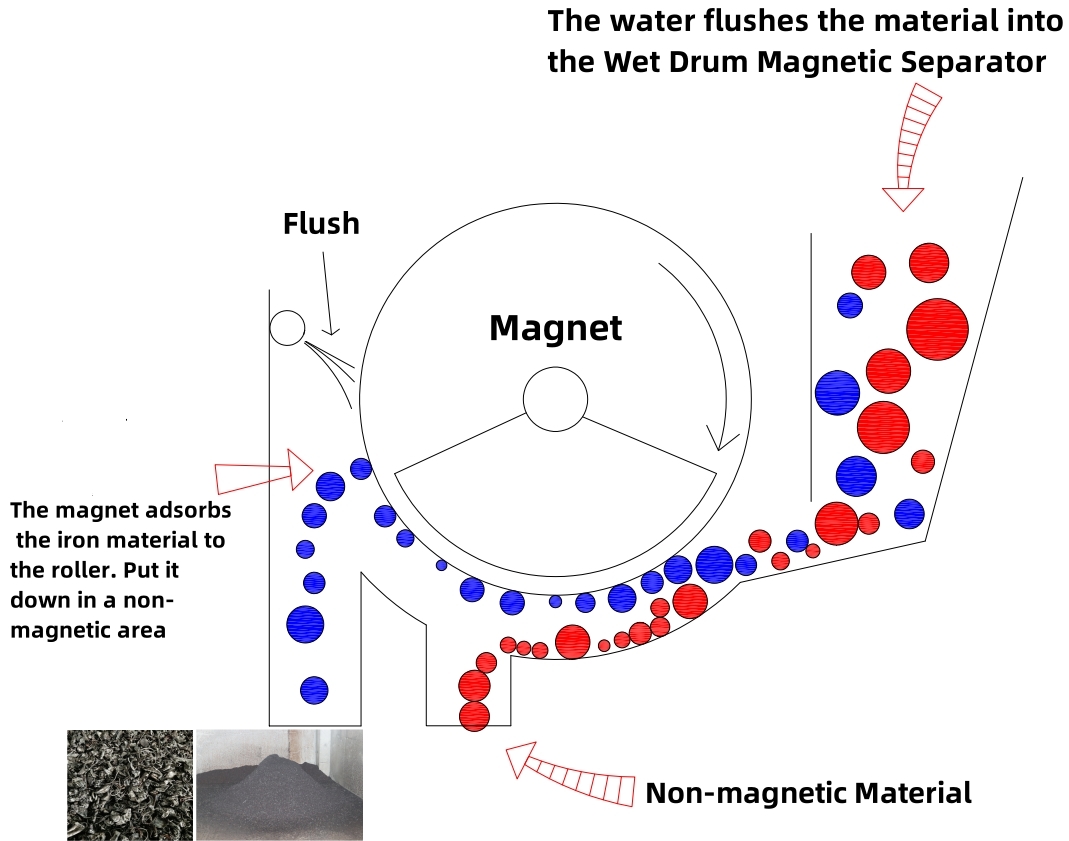

Drum Type Wet Magnetic Separator Principle

The wet type drum magnetic separator operates through a three-stage process to achieve efficient magnetic separation:

Adsorption

When water-mixed material enters the magnetic drum's working zone, ferromagnetic particles are adsorbed onto the high-intensity drum surface, forming stable magnetic chains.

Conveyance

The rotating drum transports the adsorbed magnetic particles to the fine-material outlet, separating them from non-magnetic tailings in the process.

Flushing & Collection

High-pressure water from the ore pipe flushes the magnetic particles off the drum surface, completing the separation and collecting the concentrated magnetic material.

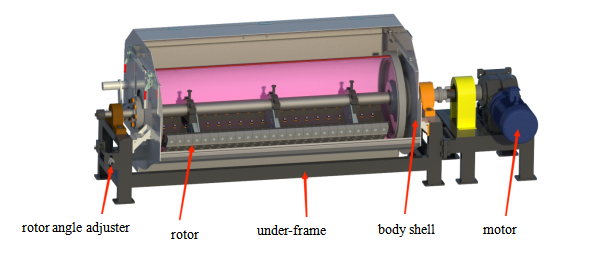

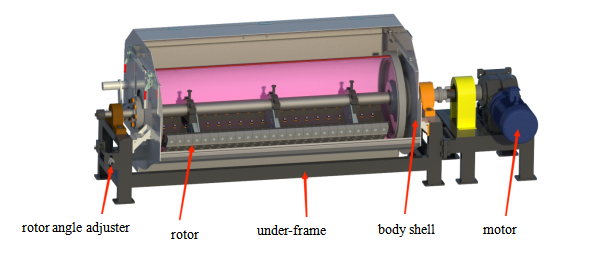

The wet drum magnetic separator adopts the principle of magnetic blocks to absorb iron materials for separation. It is generally composed of top cover, body shell, flushing water pipe, magnetic drum, motor, etc. It has the characteristics of simple structure, large processing capacity, high magnetic separation rate, and long service life.

Automated Wet Drum Magnetic Sorting Machine Features

Low demagnetization rate, high magnetic separation accuracy;

Adjustable angle as per actual needs.

Thick stainless - steel drum, wear - resistant and durable.

Large processing capacity, high magnetic separation rate.

Stable operation, low failure rate, long service life.

Simple & compact structure, easy to install and integrate into existing systems.

Open magnetic system (150°magnetic wide angle), yielding high - grade minerals with minimal tailings.

Magnetic Drum Separators Structure

Magnetic Drum Separators Equipment Technical Parameter

Model | Dimensions (L*W*H)(mm) | Drum Length(mm) | Processing Capacity(t/h) | Weight(kg) |

CTS-50090L | 1758x952x1017 | 900 | 15~20 | 810 |

CTS-50120L | 2058x952x1017 | 1200 | 20~25 | 930 |

CTS-50150L | 2426x952x1017 | 1500 | 25~30 | 1055 |

Wet Magnetic Separator Field Use Video

Ruijie utilizes China‘s premium rare earth magnetic material (NdFeB) in its structure design. It prevents wear through wear-resistant aluminum or stainless steel housings, end flanges, and lubricated bearings, ensuring extended operating hours.

The following is one of our customer's incineration Bottom ash (IBA) sorting plants, where the wet magnetic separator machine is primarily employed to screen ferrous materials with an extremely high iron removal rate of 99%

Non-demagnetization Reliable Durable Wet Drum Magnetic Separator Application Area

Ruijie industrial wet magnetic separator is widely used in a wirange of field, such as mining, metallurgy, building materials.It has gained popularity for its high efficiency, energy saving and eco-friendliness.

Iron Material Separated By the Automated Wet Drum Magnetic Separator

The following are the iron materials that extracted from the incineration ash (IBA) by wet separation, with purity reach 100% purity. The size of the obtained ferrous material can be adjusted as required.