High-effective Reliable Eddy Current Separator Application

The high-efficiency and reliable eddy current separator is mainly used in the crushing and recycling processes of various waste materials, such as circuit boards, waste doors and windows, end-of-life vehicles, and waste household appliances.

This eddy current separator can effectively separate various weakly magnetic non-ferrous metals , like copper, aluminum, tin, zinc, stainless steel, from crushed materials. It delivers significant economic and environmental value.

In addition, it is also widely used in domestic and international incineration base ash (IBA) sorting plants for the separation of copper and scrap aluminum.

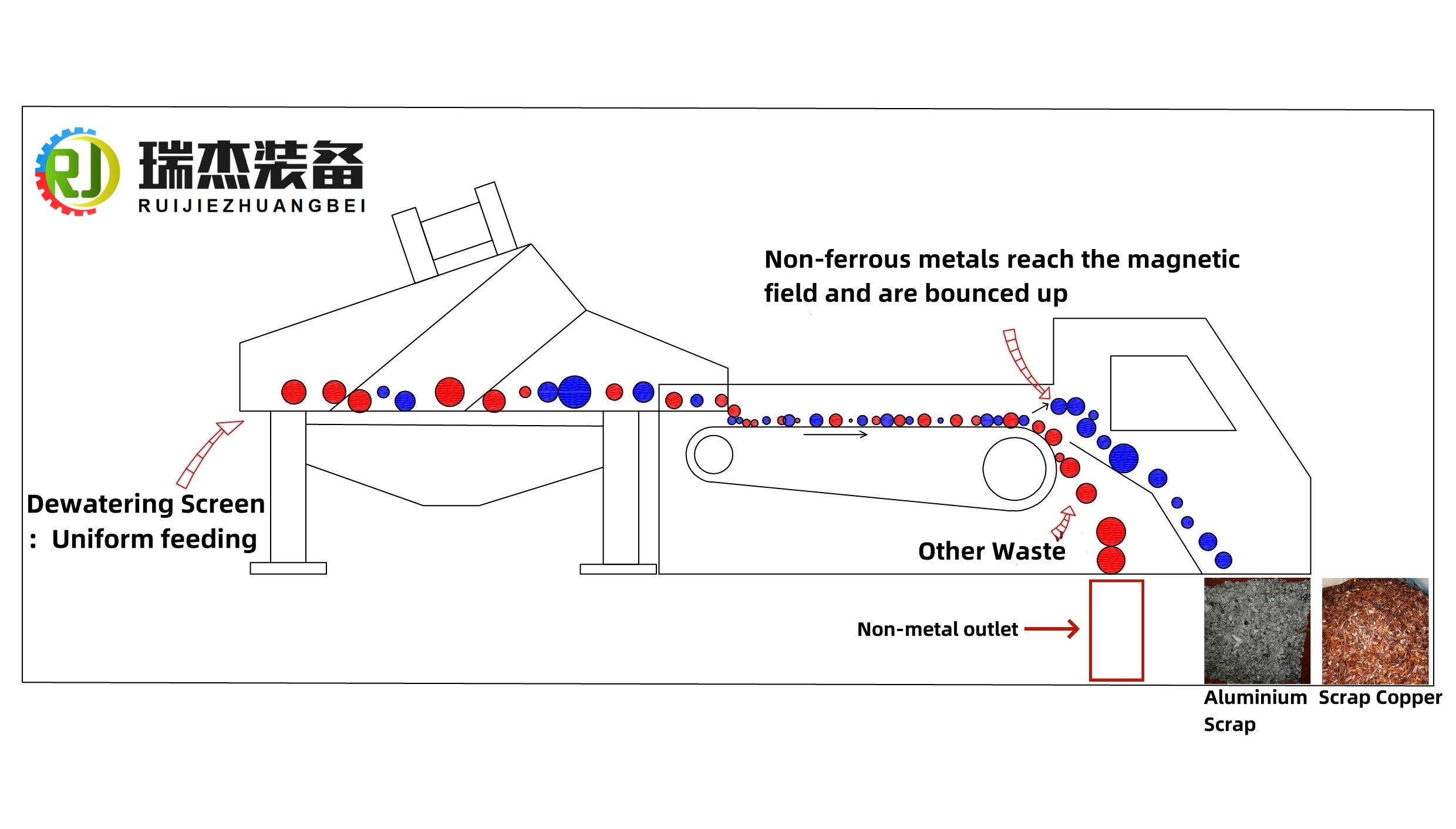

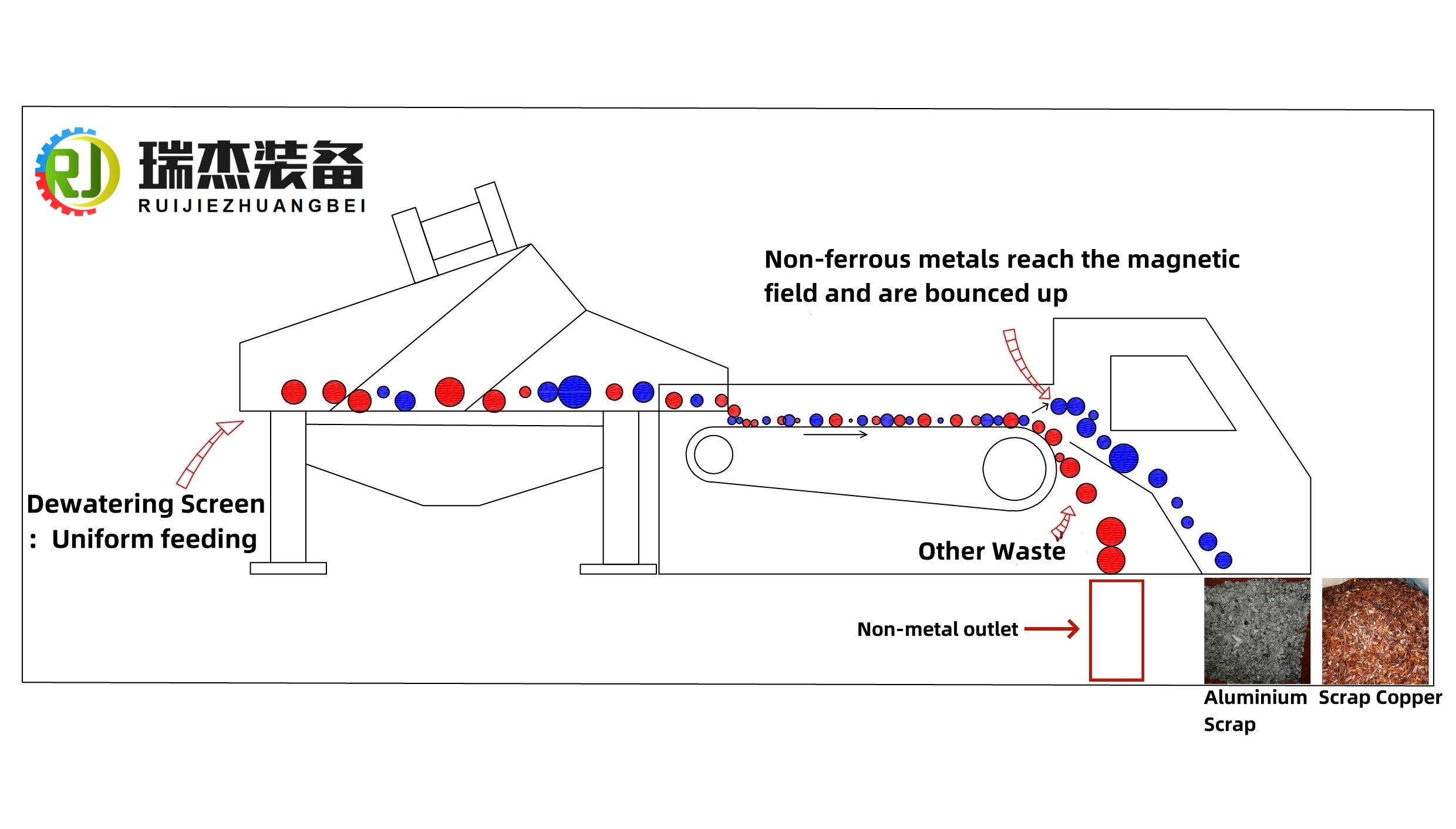

High-effective Eddy Current Separator Principle

The working principle of the high-efficiency eddy current separator relies on the eddy current effect of metals. A high-speed rotating magnetic drum inside the eddy current separator generates a magnetic field. When materials pass through this magnetic field, an induced magnetic field is created inside the metals—with a direction opposite to the original magnetic field. The metals are then thrown out by the repulsive force of this induced magnetic field.

ECS Eddy Current Separator Features

● Delivers consistent performance with low failure occurrences and a prolonged operational lifespan.

● Utilizes well-recognized accessories from both home and overseas, providing quality assurance.

● Features compact construction, hassle-free installation, and seamless integration into existing setups.

● Equipped with a distribution plate adjustable in six directions, enabling precise and adaptable material feeding.

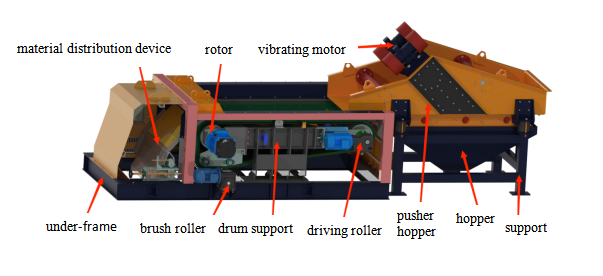

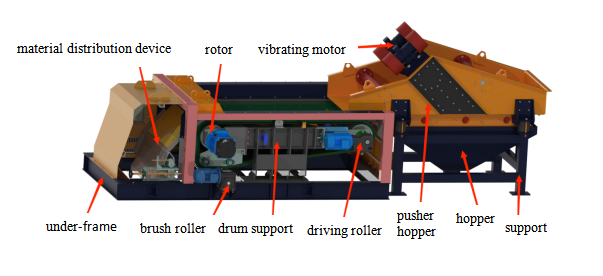

RUIJIE Eddy Current Separator Structure

RUIJIE Eddy Current Separator Machine Technical Parameter

Model | Dimensions (L*W*H) (mm) | Effective Belt Width(mm)

| Feeder Specification(mm) | Processing Capacity(t/h) |

RJ065AL-R | 3311x1778x1297 | 650 | 1817x923x1666 | 2~8mm,2t/h 8~30mm,4t/h 30~80mm, 6.5t/h |

RJ080AL-R | 3311x1982x1297 | 800 | 2240x1140x1839 | 2~8mm,2.5t/h 8~30mm,5t/h 30~80mm,8t/h |

RJ100AL-R | 3311x2186x1306 | 1000 | 2593x1356x1903 | 2~8mm,3.5t/h 8~30mm,6.8t/h 30~80mm,10t/h |

RJ150AL-R | 3311x2646x1306 | 1500 | 2593x1816x1929 | 2~8mm,6t/h 8~30mm,12t/h 30~80mm,15t/h |

Single Layer Eddy Current Sorter Working Principle Diagram

RUIJIE eddy current separator is named after the fact that it works on the principle of eddy current. This is a purely physical solid-waste sorting method that utilizes the characteristics of non-ferrous metals, and the sorting efficiency has been significantly improved compared to traditional sorting methods. According to different materials, its sorting efficiency is around 98%.

The Material Sorted Out By the RUIJIE Single-layer Eddy Current Separator

Ruijie eddy current separation machines are used in various recycling fields, and our customers are all over the world, most of them are in the field of scrap metal recycling. Our strict quality control, excellent after-sales service, and higher sorting purity and efficiency than industry peers, have won us favor among domestic and foreign customers.

Eddy Current Separator Used In IBA Wet Sorting Project

The eddy current separator plays an important role in the incineration bottom ash(IBA) wet sorting production line, it can help remove aluminum, copper and other non-magnetic metal from the mixed materials, achieving the goal of high purtity and high recovery. Accoding to specific application requirements, the size of aluminum or other materials can be adjusted by adjusting the distrinution device.

Advantages of Ruijie Eddy Current Separator