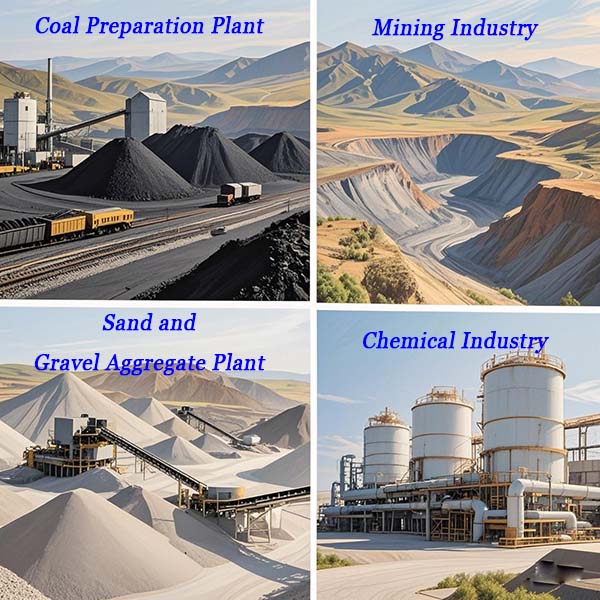

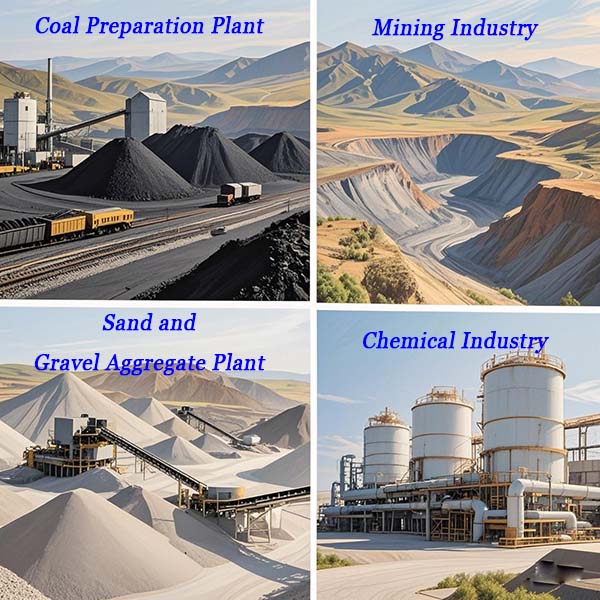

Application

The dewatering screen allows adjustable excitation force based on material moisture levels.

With its sturdy structure, simple operation, and low maintenance requirements, it delivers outstanding screening performance across a range of industrial sectors, such as:

Construction waste recycling (mud removal and aggregate drying)

Quarry sand processing (dewatering of washed sand for quality improvement)

Industrial sludge treatment (solid-liquid separation for waste reduction)

Principle

The side-plate motor series dewatering screen adjusts vibration amplitude and excitation force via the eccentric blocks of its side-plate vibration motors. Four individual side-plate vibration motors are synchronously and reversely linked through universal drive shafts.

Centrifugal forces from the four motors and eight eccentric block sets are superimposed along the vibration direction, while reverse centrifugal forces are offset. This generates a single directional excitation force that drives linear movement of the screen deck, enabling efficient material screening, classification and dehydration.

Excitation force can be fine-tuned based on material moisture: higher force for drier materials, lower force for wetter feedstock. Dehydrated materials are discharged directly from the outlet end.

Feature

● Compact, lightweight design with a simplified structure for easy installation and maintenance;

● Low noise, low power consumption, and high operational efficiency;

● High screening precision, zero dust pollution, and eco-friendly performance;

● Multi-screen replacement capability for extended service life;

● Equipped with a block eccentric self-synchronous exciter;

● Versatile application for both inclined and horizontal installation scenarios.

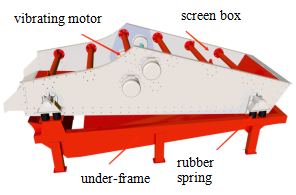

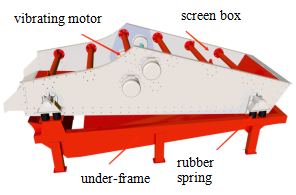

Structure

Technical Parameter

Model | Screen Area(㎡) | Processing Capacity(t/h) | Feed Size (mm) | Weight (kg) | Dimensions (mm) |

TSS21025 | 2.5 | 10-30 | ≤10 | 2150 | 2600×1570×1575 |

TSS21524 | 3.6 | 20-40 | ≤10 | 2368 | 2750×2070×1853 |

TSS21842 | 7.86 | 50-70 | ≤10 | 5430 | 4860×2470×2567 |

TSS41842 | 7.86 | 60-80 | ≤10 | 6250 | 4900×2470×2785 |

TSS41860 | 10.2 | 100-120 | ≤10 | 7850 | 6100×2470×2910 |

TSS42460 | 13.26 | 140-160 | ≤10 | 8750 | 6100×3070×2910 |

TSSJ42460 | 13.26 | 100-140 | ≤10 | 9060 | 6224×3000×2765 |

Industrial Application

The vibrating dewatering screen is widely applicable across a diverse range of industrial sectors, including coal preparation plants for coal slime recovery and dewatering, mineral processing operations, sand and gravel aggregate production facilities, as well as chemical manufacturing industries.