Application

Screw conveyor is a conveying machine that can continuously and efficiently transport powdery, granular, or small lumpy materials such as cement, fly ash, mineral powder. It pushes materials along the trough through the rotation of spiral blades, enabling horizontal, inclined, or vertical material transfer.

Principle

The screw conveyor operates by means of a rotating spiral blade that propels materials through its trough.

As the screw shaft rotates, the combined effect of the material’s own weight and the friction between the material and the trough wall prevents the material from rotating alongside the blade.

Instead, it can only move forward along the bottom of the conveyor trough—much like a stationary nut moving linearly along a rotating bolt.

The primary driving force for the material’s advancement comes from the axial rotational force of the spiral blade, which pushes the material upward and forward along the blade’s tangential direction.

Feature

Structural & Operational Advantages: Compact structure, small volume, light weight, reliable operation, high conveying efficiency, and convenient maintenance and management.

Material Adaptability:Capable of transporting high-moisture materials; inclined installation enables a certain filtering effect.

Environmental Performance: Enclosed tank body is suitable for conveying dust-prone materials and reduces environmental pollution.

Wear-Resistant Tank Design: Fully lined with replaceable ultra-high molecular polyethylene, featuring strong wear resistance and long service life.

Durable Blades: Spiral blades are equipped with large-diameter rubber plates, enhancing wear resistance, reducing the replacement frequency of wearing parts, and prolonging the equipment's service life.

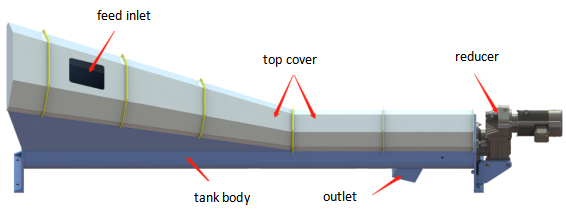

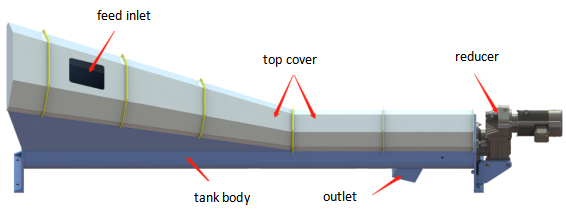

Structure

Technical Parameter

Model | Spiral Diameter (mm) | Tank Length (mm) | Rotation Speed (r/min) | Processing Capacity(t/h) | Power(kw) | Dimensions (L*W*H)(mm) | Weight(kg) |

LS3000 | 320 | 3000 | 17 | 6-8 | 3 | 3755×1200×1170 | 870 |

The tank length and rotation speed can be customized. |

Advantages

Material transfer: Connect different equipment on the production line to complete point-to-point transportation of raw materials, semi-finished products, or finished products—such as from silos to crushers, or from screening machines to storage tanks.

Quantitative conveying:Equipped with a speed control device, it can accurately adjust the material conveying capacity to meet process requirements like batching and metering, commonly used in chemical, food processing, and other industries.

- Adaptation to complex working conditions: Capable of conveying in a closed environment to reduce dust pollution, it can also handle high-temperature or corrosive materials (with special materials), covering mining, building materials, grain, environmental protection, and other fields.