Application

Wheel sand washing machines are popular in sectors like sand and gravel fields, mines, building materials, transportation, water conservancy and hydropower, concrete mixing stations, and more.

Its primary function involves washing, grading, and dehydrating quartz sand utilized by glass factories; backfill sand needed for oil wells; and unit sand & foundry sand essential at construction sites, plants dealing with sand and gravel, concrete dams for hydropower stations, posts, and telecommunications pole factories.

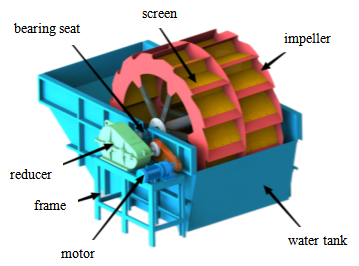

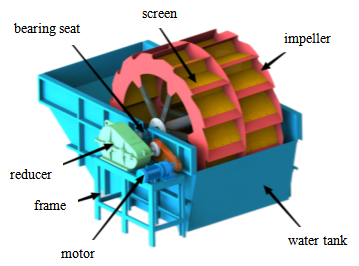

Principle

In the wheel sand washing machine, the motor drives the impeller to rotate slowly after decelerating through the triangle belt, reducer and gear. The sand enters the washing tank from the feed trough, rolls under the drive of the impeller, and grinds each other to remove surface impurities and destroy the water vapor layer covering the sand to facilitate dehydration; at the same time strong water flow is formed by adding water which remove impurities and small specific gravity foreign matters in a timely manner and carries them out from the overflow outlet of the washing tank. Clean sand will be carried away by blades and poured from the rotating impeller into discharge chute completing the cleaning function of sand.

Feature

●Reasonable structure, convenient maintainance;

●Water-saving, no pollution;

●Convenient to use, economical and durable

●Large output, high cleanliness, minimal sand loss during sand washing;

●Except for the screen, this machine has almost no wearing parts

●Long service life and no need for long-term maintenance;

Powerful function

The wheel sand washing machine can wash various of rocks, sand, with excellent effect. It features high cleaning efficiency, large output, and a lower failure rate than conventional sand washers, making it the optimal choice for upgrading in the sand washing industry.

Structure

Technical Parameter

Model | Weight(kg) | Processing Capacity(t/h) | Feed Size(mm) | Power(kw) | Dimensions(L*W*H)(mm) |

HLX1809 | 2456 | 20~40 | ≤6 | 3 | 2620x2330x1970 |

HLX2412 | 3764 | 30~50 | ≤6 | 3 | 3280x2410x2545 |

HLX3018 | 5488 | 50~80 | ≤6 | 7.5 | 4690x3670x3070 |

HLX4018 | 7072 | 80~150 | ≤6 | 7.5 | 5880x3630x4060 |

Applicable to Various Scenarios

The durable wheel sand washing machine is widely used in industries such as sand and gravel yards, mining, building materials, transportation, chemical engineering, water conservancy and hydropower, and concrete mixing stations for material washing.