Aplay fɔm

Skru kɔnvaysɔ na wan . Conveying mashin we kin kɔntinyu fɔ transpɔt paoda, granul, ɔ smɔl smɔl lumpy matirial dɛn lɛk simen, flay ash, minral paoda . I de push matirial dɛn along di trowe tru di roteshɔn fɔ spiral bled dɛn, we de mek ɔrizɔntal, inklin, ɔ vertikal matirial transfa.

Prinsipul .

Di Skru kɔnvaysɔ de wok bay we dɛn de yuz wan spiral bled we de rɔn we de push matirial dɛn tru in trowe.

As di skru shaft de rɔn, di kɔmbayn ifɛkt we di matirial in yon wet ɛn di frikshɔn bitwin di matirial ɛn di trough wɔl de mek di matirial nɔ de rɔn nia di bled.

Bifo dat, i kin jɔs go bifo along di bɔt ɔf di kɔnvaysɔ trowe—i tan lɛk wan steshɔnari nut we de muv linya wan along wan bolt we de rɔn.

di praymar drivin fכs fכ di mεtirial in advansmεnt kכmכt frכm di akshal rotashכnal fכs fכ di spiral bled, we de push di mεtirial כp εn fכdכn along di bled in tanjεntal dairekshכn.

Tin

Structural & Opareshonal Advantej S: Kɔmpakt strɔkchɔ, smɔl volyum, layt wet, ɔpreshɔn we dɛn kin abop pan, ay kɔnvɛyshɔn efyushɔn, ɛn kɔvinant mentenɛns ɛn manejmɛnt.

Material Adaptability: I kin ebul fɔ transpɔt ay-mɔystɔ matirial dɛn; Inklin inst ɔ leshɔn de mek yu ebul fɔ gɛt sɔm filta ifɛkt.

Envairomɛnt pefɔmɛns: Ɛnklɔz tank bɔdi fayn fɔ kɛr dɔst-prone matirial ɛn ridyus envayrɔmɛnt pɔyushɔn.

Tank dizayn we nɔ de wear: ful layn wit riplesabl ɔltra-hay mɔlikul polyethylene, we gɛt strɔng wear resistans ɛn lɔng savis layf.

Bled dɛn we kin te: Dɛn kin yuz spiral bled dɛn wit big big rɔba plet dɛn we gɛt big dayamita, fɔ mek dɛn nɔ west, fɔ ridyus di chenj we dɛn kin yuz fɔ chenj di pat dɛn we dɛn kin wɛr, ɛn fɔ mek di ikwipmɛnt in savis layf lɔng.

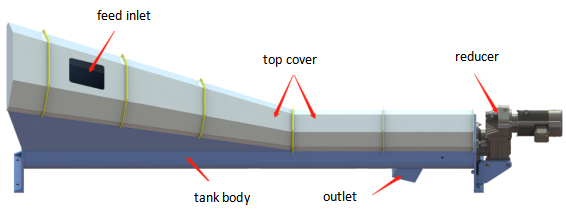

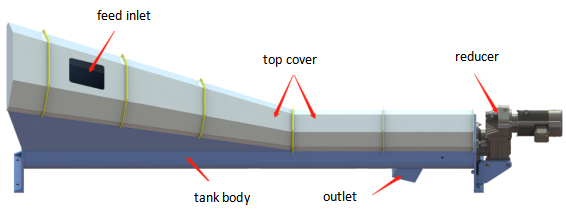

Bildin

Teknik Paramita .

Ɛgzampul |

spiral dayamita . (mm) |

Tank lɔng . (mm) |

Roteshɔn . Fas fas (R/Min) |

Prɔsesin . Kapasiti(T/H) we de na di wɔl. |

pawa (kw) Di wan dɛn we de wok. |

Dimenshon dem . (l*w*h)(mm) |

wet (kg) |

LS3000 na di . |

320 |

3000 |

17 |

6-8. |

3 |

3755×1200×1170 we dɛn rayt. |

870 |

Di tank lɔng ɛn roteshɔn spid kin kɔstɔmayz. |

Di bɛnifit dɛn we pɔsin kin gɛt .

Material Transfer: Kɔnekt difrɛn ikwipmɛnt dɛn na di prodakshɔn layn to kɔmplit pɔynt-to-pɔynt transpɔt fɔ raw matirial, sɛmi-finished prodak, ɔ finish prodak—lɛk frɔm saylɔs to krɔsh, ɔ frɔm skrinin mashin to stɔrɔj tank.

Kwantitaytiv Kɔnvɛyshɔn: I gɛt spid kɔntrol divays, i kin ajɔst di matirial kɔnvɛyshɔn kapasiti kɔrɛkt wan fɔ mit di prɔses rikwaymɛnt dɛn lɛk batch ɛn mita, we dɛn kin yuz mɔ pan kemikal, it prɔsesin, ɛn ɔda industri dɛn.

- Adapshɔn to kɔmpleks wok kɔndishɔn: we ebul fɔ kɛr insay ples we dɛn dɔn lɔk fɔ ridyus di dɔti we de pwɛl di dɔst, i kin ebul bak fɔ handle ay-tɛmpracha ɔ kɔrɛkt tin dɛn (wit spɛshal matirial dɛn), we de kɔba mayning, bildin matirial, gren, envayrɔmɛnt protɛkshɔn, ɛn ɔda fil dɛm.