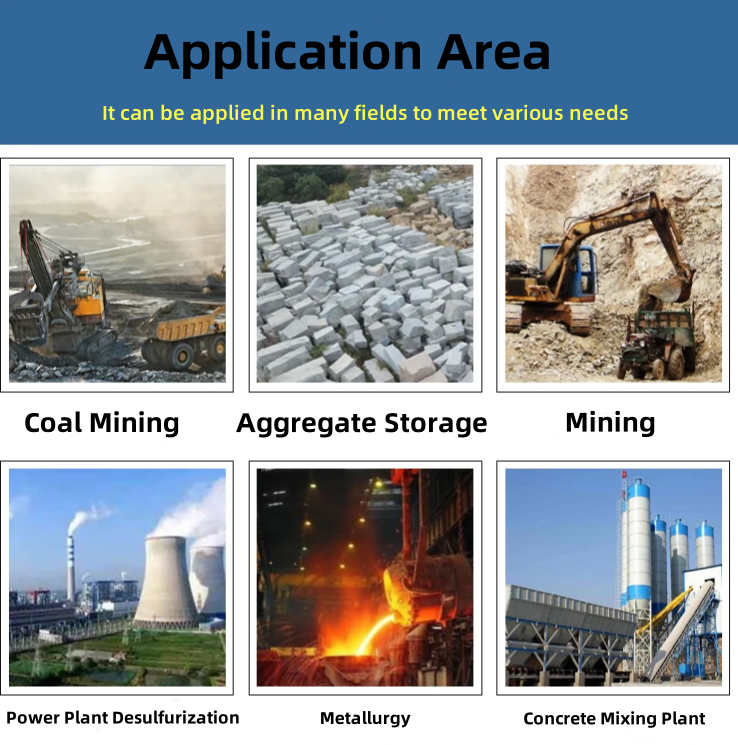

Application

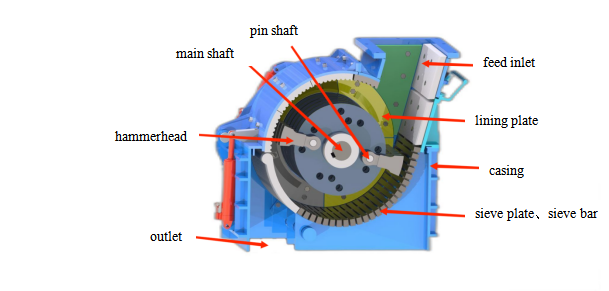

The copper hammer crusher consists of a power unit, transmission system, bearings, rotor, housing, and wear-resistant components. It integrates three crushing methods—striking, counterattack, and impact—into a single processing stage, delivering high efficiency, increased output, and reduced operational costs.

This equipment is widely applied in sectors including non-ferrous metal recycling, copper smelting & processing, e-waste treatment, casting, and machining.

Principle

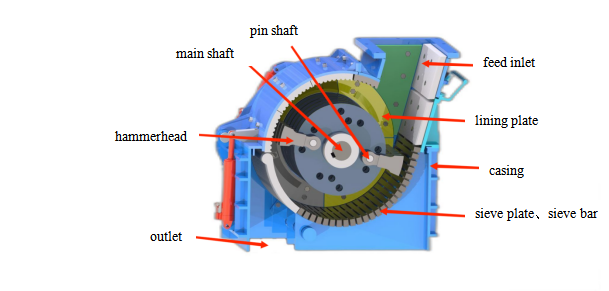

Materials are fed into the inlet of the hammer crusher and crushed by high-speed rotating hammers via the combined actions of striking, shearing, impacting, and grinding. A sieve plate or sieve bar are installed beneath the rotor. Particles smaller than the sieve hole pass through the openings and are discharged, while oversized coarse particles remain on thesieve plate. These larger particles are repeatedly impacted and crushed by the hammers until they are reduced to a size small enough to pass through the sieve hole and exit the machine.

Feature

● Streamlined, robust structure with low operational costs and convenient maintenance.

● High crushing efficiency paired with minimal energy consumption.

● Integrates both fine crushing and coarse grinding capabilities in one unit.

● Minimal performance impact from material moisture content, with reliable anti-leakage design.

● Optimized specifically for slag material crushing applications.

●Uniform, cube-shaped end products with extremely low needle and flake content

● Superior wear and corrosion resistance for extended service life.

Structure

Technical Parameter

Model | Feed Inlet (mm) | Power (kw) | Processing Capacity (t/h) | Dimensions (L*W*H)(mm) | Weight (kg) |

PC-TT400 | 230×230 | 30-60 | 1-2 | 1390×1085×1160 | 1480 |

PC-TT500 | 230×230 | 30-60 | 2-3 | 1370×1400×1110 | 1634 |

PC-TT650 | 400×210 | 40-80 | 3-5 | 1365×1500×1090 | 1704 |

Applicable to Various Scenarios

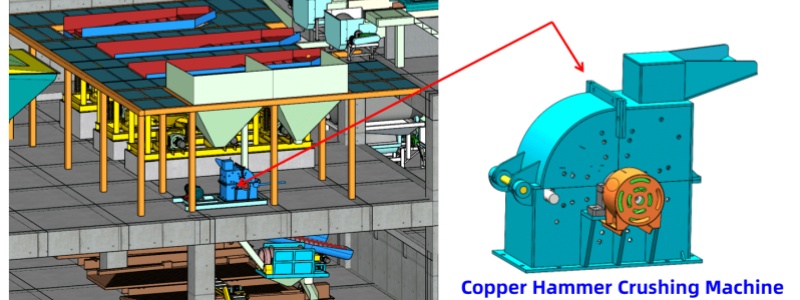

Production Line

The copper hammer crusher is perfectly compatible with incineration bottom ash(IBA) wet sorting production lines, serving as a dedicated crushing unit for copper-containing materials. Its flexible modular design allows for customized installation that aligns with on-site layout requirements and the overall process flow of the production line.