Application

Trommel screen, also called rotary screening machine or drum screening machine, its core component is a multi-mesh circular screening cylinder. It efficiently classifies hard and inert materials of varying sizes and proportions in mixed solid waste, slashing labor intensity.

Key Applications:

Municipal solid waste treatment (pre-screening for recycling/disposal)

Construction waste recycling (aggregate size sorting)

Mining & mineral processing (ore grading)

Power plants & building materials factories (fuel/raw material classification)

Principle

The working principle of the trommel scrren : waste is fed into the hopper and conveyed to the rotating screening drum. Constant tumbling, impact, and friction inside the drum separate materials by size: small particles fall through the screen holes, while large waste is discharged via the outlet—completing efficient size classification.

Feature

●High Screening Efficiency:TLarge effective screening area enables full material-screen contact, delivering high throughput per unit time.

● Precise Screening Accuracy:Continuous tumbling and rolling of materials inside the drum prevents accumulation and clogging, ensuring consistent screening precision.

● Strong Adaptability: Adjustable drum speed and inclination angle to meet screening needs of diverse materials.

● Easy Maintenance: Simplified structure allows for straightforward upkeep operations.

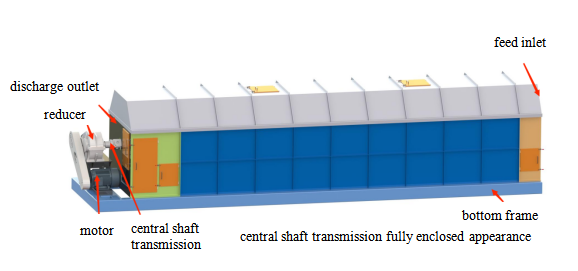

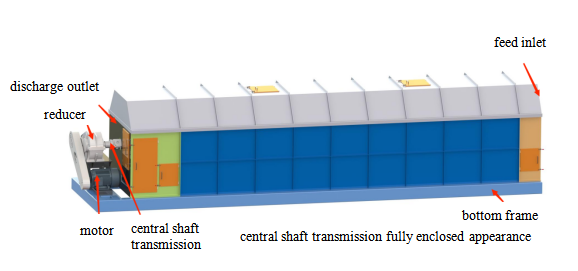

Structure

This trommel screen features a streamlined, fully enclosed design (fully/semi-enclosed optional), with key components:

Feed Inlet: For material loading

Central Shaft & Transmission: Drives drum rotation

Reducer & Motor: Power system

Bottom Frame: Provides stable support

Discharge Outlet: For material output after screening

Technical Parameter

Model | Power (kw) | Cylinder Rotation Speed(r/min) | Maximum Feed particle size(mm) | Processing Capacity (t/h) | Weight (kg) | Dimensions(mm) |

GTS0612 | 1.5 | 23 | Mesh Size×2.5 | 2-10 | 600 | 2150×820×823 |

GTS1245 | 7.5 | 20 | Mesh Size×2.5 | 20-50 | 2500 | 6328×1750×1700 |

GTS1360 | 11 | 20 | Mesh Size×2.5 | 25-60 | 3800 | 7828×1800×1784 |

Intergrated in Production Line

When integrate in (Incinerator Bottom Ash) IBA wet sorting line, this trommel screen serves key functions:

Separates large/small incinerator bottom ash

Screens large/small iron scraps

Removes floating waste

Classifies materials by particle size