Application

The jig machine is a high-efficiency energy-saving gravity separation equipment used for copper, silver, tin and other non-ferrous metal separation in the mineral processing, metal recovery operations.

This high recovery rate jig machine developed based on the traditional sine wave jig machine.

Its key difference from the traditional sine wave type lies in its sawtooth-wave flow fluctuation curve: the ascending water flow is fast while the descending water flow is slow.

Driven by the ascending flow, the mineral bed rises and loosens, then settles slowly—this extends the effective separation time, significantly reducing both the required under-screen makeup water and the lower limit of recoverable particle sizes.

Compared with the sine wave jig machine, its operational recovery rate increases by 3.01% for tin (Sn) and 5.5% for tungsten (W), while water consumption decreases by 30–40%.

Principle

The jig separator works based on specific gravity differences between ore and gangue. When the mineral mixture, which contains minerals of different specific gravities, is fed into the jigging chamber filled with water, the pulsating water flow causes the particles to move and interact with the water.Heavier minerals with a higher specific gravity tend to sink to the bottom of the jig sorting tank, because they are less affected by the upward - moving water flow. Lighter minerals or gangue with a lower specific gravity are more easily lifted and carried by the water flow, remaining in the upper part of the jig separator sorting tank. Then, different minerals can be precisely separated.

Feature

● With 1.2㎡ jigging chamber, small in size, large processing capacity up to 20T/H.

● Jig frequency is 40~90c/min, can be adjusted accordingly.

● The use of cam mechanism transmission effectively improves the recovery rate of fine grained useful minerals.

● The sawtooth-wave jig has pulsating water flow in a sawtooth pattern, with water efficiency and long continuous runtime.

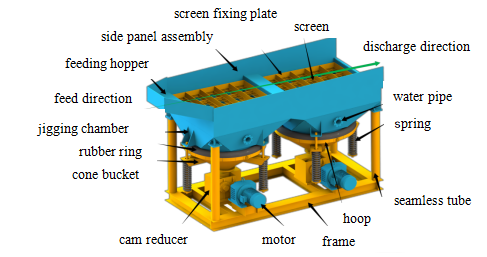

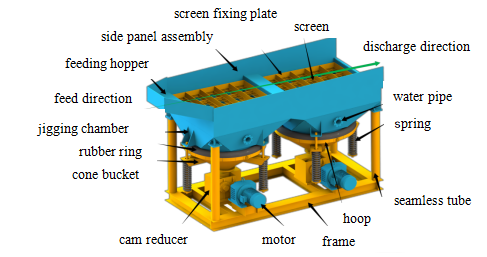

Structure

Technical Parameter

Trapezia

Model | Jigging Chamber | Feed Particle Size (mm) | Supply Water Under Screen ( ) ) | Supply Water Pressure Under Screen (Mpa) | Processing Capacity (t/h) | Power (kw) | Dimensions (L*W*H) (mm) | Weight (kg) |

Shape | Area ( ㎡) ㎡) |

| JTY1.2 | Trapezia | 1.2 | <15 | 3-6 | ≥0.1 | 10-20 | 5.5 | 1652x1826x2122 | 1585 |

JTY21 | Trapezia | 2.25 | <15 | 3-6 | ≥0.1 | 15-35 | 5.5 | 2230x1740x2600 | 2100 |

JTY42 | Trapezia | 4.5 | <15 | 30-50 | 5.5x2 | 4030x1980x2650 | 4200 |

JTY63 | Trapezia | 6.75 | <15 | 40-70 | 5.5X2,7.5X1 | 5560x1885x2650 | 5916 |

JTY82 | Trapezia | 8 | <15 | 60-90 | 11x2 | 5200x2050x3250 | 8365 |

)

)