Jig mashin dɛn dɔn bi wan impɔtant pat pan difrɛn industri dɛn, we dɔn rivɔlɔshɔn di prɔses fɔ separet difrɛn matirial dɛn fayn fayn wan ɛn fayn fayn wan. Insay dis atikul, wi go delv insay di wɔl fɔ jig mashin dɛn, fɔ fɛn ɔl di tin dɛn we dɛn de du, aw dɛn de yuz dɛn, di bɛnifit dɛn we dɛn gɛt, ɛn di tin dɛn we dɛn fɔ tink bɔt we dɛn de pik di rayt wan fɔ yu patikyula nid dɛn.

Fɔ bigin, wi go unravel di wok we wan jig mashin de du, ɔndastand di mɛkanism dɛm we de mek i ebul fɔ ajɔst di optimum separeshɔn rizɔlt dɛm. Aw jig mashin de wok ? Wi go gi wan kɔmprɛhɛnsif ɔvaviu fɔ di stɛp-by-stɛp prɔses dɛn we involv, shed layt pan di sɛnsful injinɛri biɛn dis wɔndaful divays.

We wi de muf go bifo, wi go fɛn di bɔku bɔku aplikeshɔn dɛn we jig mashin dɛn de kia fɔ. Frɔm minral prɔsesin ɛn kol was to mɛtal rikavari ɛn ore bɛnifit, dɛn versatile mashin ya dɔn fɛn dɛn ples na bɔku industri dɛm. Aplikeshɔn fɔ JIG mashin dɛn go sho di difrɛn difrɛn sɛktɔ dɛn we de bɛnifit frɔm dɛn yutilizeshɔn ɛn aw dɛn de strimlayn ɔpreshɔn fɔ ɛp fɔ mek dɛn prodaktiviti go bifo.

Dɔn bak, wi go tɔk bɔt di bɛnifit dɛn we kin kam wit yuz jig mashin dɛn. Ilɛksɛf na di ebul we dɛn ebul fɔ handle bɔku bɔku patikyula saiz dɛn, dɛn nɔ de tek bɔku mɔni, ɔ dɛn nɔ de ambɔg di envayrɔmɛnt, di bɛnifit dɛn we dɛn gɛt we dɛn de yuz jig mashin dɛn go sho di bɔku bɔku bɛnifit dɛn we de mek dɛn pik di we aw dɛn want na bɔku industrial sɛtin dɛn.

Las las, wi go delv insay di tin dɛn we wi fɔ tink bɔt we wi de pik jig mashin. Wit bɔku bɔku opshɔn dɛn we de na di makit, i rili impɔtant fɔ mek dɛn disayd fɔ du sɔntin we dɛn no bay we dɛn yuz patikyula tin dɛn we dɛn nid. Di tin dɛn we yu fɔ tink bɔt we yu de pik wan jig mashin go gi valyu tin dɛn fɔ ɛp fɔ mek dɛn disayd fɔ du sɔntin, ɛn mek shɔ se dɛn pik di mashin we go fayn pas ɔl fɔ mek dɛn gɛt di bɛst rizɔlt.

Fɔ dɔn, dis atikul gɛt fɔ du wit fɔ mek ɔlman ɔndastand di jig mashin dɛn, di we aw dɛn de wok, di we aw dɛn de yuz dɛn, di bɛnifit dɛn we dɛn gɛt, ɛn di men tin dɛn we dɛn fɔ tink bɔt we dɛn de pik di rayt wan. Ilɛksɛf yu na pɔsin we sabi du in wok we de luk fɔ mek yu gɛt mɔ industri ɔ yu jɔs want fɔ no mɔ bɔt dis nyu teknɔlɔji, dis atikul go bi valyu tin fɔ pul di sikrit dɛn bɔt jig mashin dɛn.

Aw jig mashin de wok?

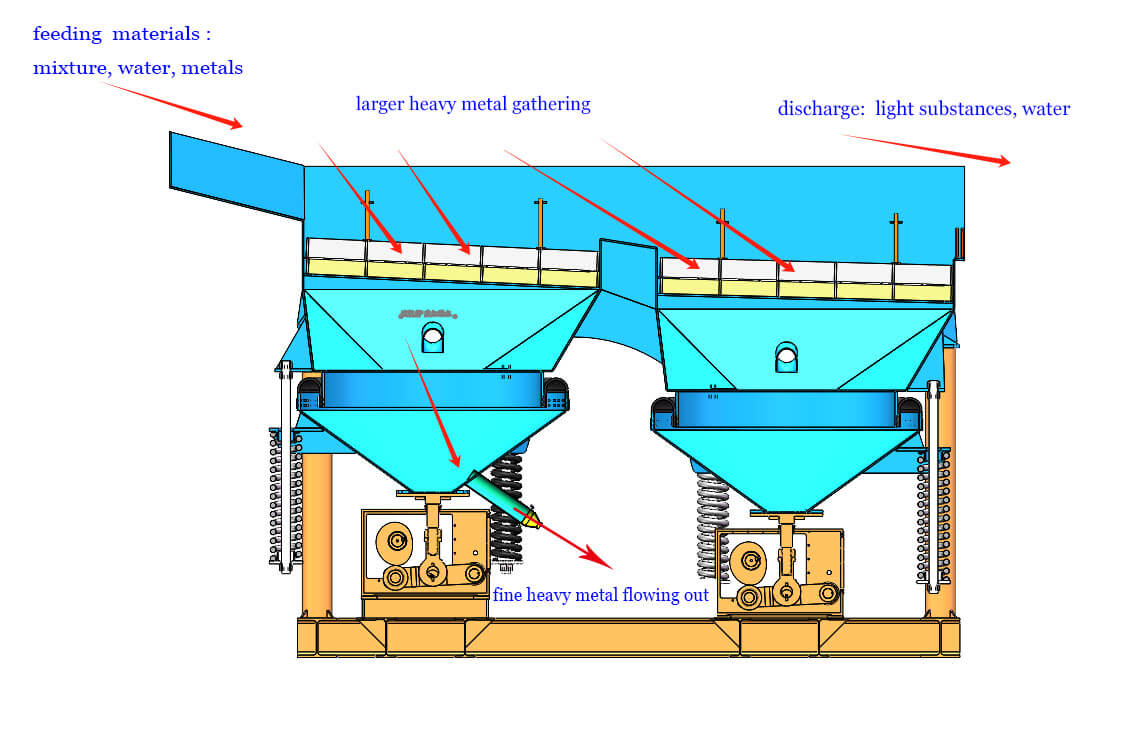

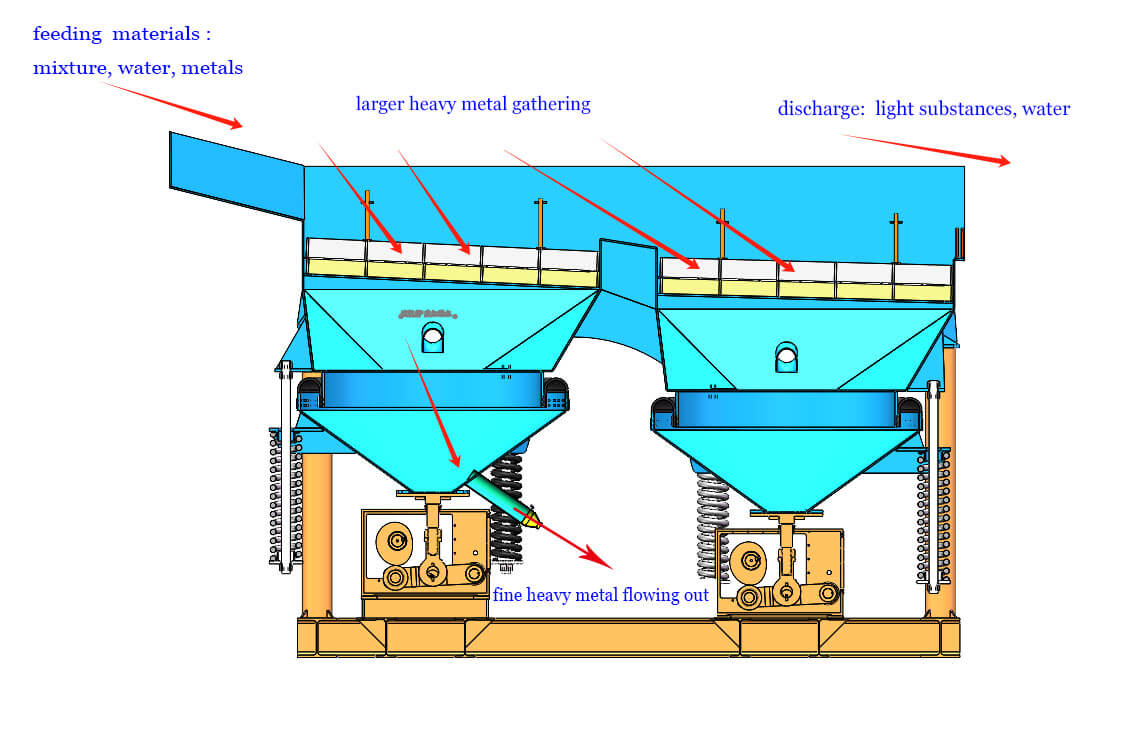

Jig mashin na wan impɔtant tin we dɛn kin yuz fɔ du difrɛn difrɛn tin dɛn we dɛn kin yuz na difrɛn difrɛn industri dɛn, lɛk fɔ du mayning ɛn fɔ mek dɛn yuz minral. I praymar funkshɔn na fɔ separet valyu minral frɔm west matirial bay we dɛn yuz di prinsipul fɔ graviti separeshɔn. Bɔt aw ɛksaktɔli jig mashin de wok?

Di opareshɔn fɔ wan jig mashin kin bigin wit di fidin fɔ raw matirial dɛn insay wan spɛshal kɔntena we dɛn mek we dɛn kɔl jigging chamber. Dis chɛmba gɛt skrin ɔ siev fɔ klas di patikyula dɛn bay we dɛn saiz. Big big pat dɛn kin lɛf pan di siev mɛsh, we smɔl smɔl tin dɛn kin fɔdɔm insay di jig chɛmba frɔm di siev ol.

Wans dɛn dɔn klas di matirial dɛn, di jig mashin de yuz pulsating wata flɔ fɔ mek muvmɛnt insay di chɛmba. dis pulseshכn de mek di patikyula dεm stratify bay dεnsiti, wit di hεvi minral dεm we de sink to di bכtכm εn di layt wan dεm we de fכt to di tכp. Dɛn kɔl dis prɔses stratifikeshɔn.

Di nɛks tin we dɛn fɔ du fɔ mek wan jig mashin wok na di aktual separeshɔn fɔ di minral dɛn. Di patikyula tin dɛn we ebi pas ɔl, we gɛt di valyu minral dɛn, dɛn kin gɛda dɛn na di bɔt ɔf di jigging chɛmba. Dɔn dɛn kin pul dɛn patikyula tin dɛn ya tru wan valv, we dɛn kin pul di layt we dɛn kin yuz fɔ west na di tap.

fכ achiv optimal separeshכn, di jig mashin de dip pan di difrεns dεm na spεsifi k graviti bitwin di minral dεm. Speshal graviti na wan we fɔ mɛzhɔ di density fɔ wan tin we dɛn kɔmpia to di density fɔ wata. Bay we dɛn de ajɔst di pulseshɔn frikshɔn ɛn di wata flɔ rit, di ɔpreshɔn dɛn kin ɔptimayz di separeshɔn prɔses fɔ difrɛn kayn minral dɛn.

Wan pan di men bɛnifit dɛn we pɔsin kin gɛt we i yuz jig mashin na we i ebul fɔ ol bɔku bɔku patikyula saiz dɛn. Di jig mashin de yuz bɔku bɔku wan na di prodakshɔn fɔ separet kɔpa, silva, tin, tungsten, tantalum, niobium, titanium, zirconium, praymari ore ɛn plesa dɛn fɔ kromiɔm.

Aplikeshɔn dɛn fɔ Jig mashin dɛn .

Jig mashin dɛn, we dɛn kin kɔl bak jigging ikwipmɛnt, na tin dɛn we dɛn kin yuz fɔ du bɔku tin dɛn we dɛn kin yuz bɔku bɔku wan na difrɛn difrɛn industri dɛn fɔ gɛt bɔku bɔku aplikeshɔn dɛn. Dɛn mek dɛn mashin dɛn ya fɔ mek dɛn separet difrɛn tin dɛn bay we dɛn de yuz dɛn patikyula graviti, we de alaw fɔ mek dɛn ebul fɔ sɔt fayn ɛn prɛsis. Di aplikeshɔn dɛn fɔ JIG mashin dɛn difrɛn ɛn dɛn kin fɛn dɛn na mayning, minral prɔsesin, ɛn risaykul ɔpreshɔn.

Wan pan di men tin dɛn we dɛn kin yuz fɔ yuz jig mashin na di mayning industri. Dɛn kin yuz dɛn fɔ pul di minral dɛn lɛk tin, ɛn dayamɔn. Jigging equipment na patikyula effektiv fɔ separet valyu minral frɔm gang-gari matirial bays pan dɛn density difrɛns. Dis prɔses de mek shɔ se na di minral dɛn nɔmɔ we dɛn want, dɛn kin gɛda, ɛn dis kin mek di ɔl di wok we dɛn de du fɔ di mayning ɔpreshɔn go ɔp.

Apat frɔm di mayning, dɛn kin yuz jig mashin dɛn bɔku bɔku wan na di minral prɔsesin plant dɛn. Dɛn mashin dɛn ya de ple impɔtant pat pan di kɔnsɛntreshɔn fɔ valyu minral dɛn frɔm ɔyl. Bay we yu yuz di prinsipul fɔ graviti separeshɔn, jigging ikwipmɛnt kin ebul fɔ separet minral dɛn fɔ difrɛn density dɛn ifɛktiv wan. Dis kin mek dɛn ebul fɔ mek ay-grɛd kɔnsɛntret dɛn, we dɛn kin prosɛs ɔ sɛl mɔ to di kɔstɔma dɛn.

Jig mashin dɛn kin fɛn bak aplikeshɔn dɛn na di risaykul industri. Dɛn de yuz dɛn na di separeshɔn ɛn rikavari fɔ di matirial dɛn frɔm west strim. Bay we dɛn de yuz jig, tin dɛn we dɛn kin yuz bak lɛk plastic, mɛtal, ɛn glas kin sɔt bay dɛn patikyula graviti. Dis de alaw fɔ mek dɛn gɛt fayn fayn tin dɛn bak fɔ gɛt valyu tin dɛn, fɔ mek dɛn nɔ west bɔku ɛn fɔ mek dɛn kɔntinyu fɔ gɛt sastaynabiliti.

Dɔn bak, jig mashin dɛn dɔn pruv se dɛn go yusful fɔ pripia fɔ kol. Insay kol was plant, dɛn kin yuz jigging ikwipmɛnt fɔ separet kol frɔm dɔti tin dɛn, lɛk rɔk ɛn shayl. Di jigging process de mek shɔ se dɛn de prodyuz klin kol, we dɛn kin yuz fɔ pawa jenɛreshɔn ɛn ɔda industrial pɔpɔshɔn dɛn. Apat frɔm dat, di yus fɔ jig mashin dɛn we dɛn de pripia fɔ kol de ɛp fɔ ridyus di envayrɔmɛnt impak we kol mayning ɛn kɔmbɔshɔn gɛt.

Advantej dɛn fɔ yuz jig mashin dɛn .

Jig mashin dɛn dɔn bi wan impɔtant tul na difrɛn industri dɛn bikɔs ɔf dɛn bɔku bɔku bɛnifit dɛn. Dɛn mashin dɛn ya kin yuz bɔku bɔku wan fɔ mayn, fɔ prosɛs di minral dɛn, ɛn fɔ mek dɛn yuz di we aw dɛn de du ɔyl. Wit dɛn efishɔnal ɔpreshɔn ɛn rilibul pefɔmɛns, jig mashin dɛn de gi impɔtant bɛnifit to biznɛs ɛn wan wan pipul dɛn ɔl tu.

Wan pan di men bɛnifit dɛn we pɔsin kin gɛt we i de yuz jig mashin na we dɛn ebul fɔ separet difrɛn tin dɛn bay we dɛn de yuz dɛn patikyula graviti. dis prכsεs, we dεn kכl graviti separeshכn, de alaw fכ di ifektiv separeshכn fכ di hεvi εn layt patikyula dεm. Bay we dɛn de yuz di prinsipul fɔ graviti, jig mashin dɛn kin ebul fɔ separet valyu minral dɛn ifɛktiv wan frɔm gang matirial dɛn, we kin mek dɛn gɛt ay klin ɛn dɛn kin mek dɛn prodaktiviti go ɔp.

Wan ɔda bɛnifit we jig mashin dɛn gɛt na dɛn versatility. Dɛn mashin dɛn ya kin ebul fɔ ol bɔku bɔku tin dɛn, lɛk kol, ayɛn ɔyl, tin, ɛn tungsten. Dɛn kin adjɔst dɛn izi wan fɔ akɔmod difrɛn fid saiz ɛn density, we kin mek dɛn fayn fɔ difrɛn aplikeshɔn dɛn. Ilɛksɛf na fɔ roughing, klin, ɔ skavenj, jig mashin dɛn kin ebul fɔ rikavari valyu minral dɛn ifɛktiv wan ɛn maksimayz di ɔvala efyushɔn fɔ di prɔses.

Apat frɔm dɛn versatility, jig mashin dɛn de gi wan kɔst-ɛfɛktiv sɔlvishɔn fɔ minral prɔsesin ɔpreshɔn. Dɛn mashin dɛn ya gɛt smɔl pawa kɔnsɔmshɔn ɛn dɛn nid fɔ gɛt smɔl mentenɛns, we de ridyus di opareshɔnal kɔst fɔ lɔng tɛm. Dɔn bak, di ay rikavari rɛt we Jig mashin dɛn dɔn ajɔst kin kɔntribyut to inkris prɔfitabiliti, as valyu minral dɛn kin rikavari ɛn yuz dɛn fayn fayn wan.

Jig mashin dɛn kin bost bak wan kɔmpakt dizayn, we kin mek dɛn fayn fɔ ɔl tu di smɔl smɔl ɛn big big opareshɔn dɛn. Dɛn smɔl futprin de alaw fɔ izi fɔ instɔl ɛn intagrɛshɔn insay di prɔsesin plant dɛn we dɔn de. Apat frɔm dat, dɛn sabi jig mashin dɛn fɔ mek dɛn izi fɔ wok, dɛn nid fɔ gɛt smɔl trenin ɛn supavayshɔn. Dis yuz-frenli nature de mek shɔ se biznɛs dɛn kin adopt ɛn yuz jig mashin dɛn kwik kwik wan fɔ mek dɛn ɔl prodaktiviti go bifo.

Factors fɔ tink bɔt we yu de pik jig mashin .

We i kam pan fɔ pik jig mashin, sɔm tin dɛn de we dɛn nid fɔ tink bɔt. Jig mashin na impɔtant tin fɔ yuz na difrɛn difrɛn industri dɛn lɛk mayning, kɔnstrɔkshɔn, ɛn wud wok. Dɛn kin yuz am fɔ separet ɛn kɔnsɛntret difrɛn matirial dɛn bay dɛn patikyula graviti. Wit bɔku opshɔn dɛn we de na di makit, i kin rili bɔku fɔ pik di rayt jig mashin fɔ yu nid dɛn. Insay dis atikul, wi go tɔk bɔt sɔm impɔtant tin dɛn we wi fɔ tek tɛm tink bɔt we wi de disayd fɔ du dis.

Fɔs ɛn fɔs, i rili impɔtant fɔ asɛs di kapasiti ɛn saiz fɔ di JIG mashin. Di kapasiti de rifer to di amount of matiryal we di mashin kin handle pan wan givɛn tɛm. Dis na impɔtant tin fɔ tink bɔt as i de sho di efyushɔn ɛn prodaktiviti fɔ di mashin. Apat frɔm dat, di sayz fɔ di jig mashin fɔ kɔmpit wit di ples we de na yu wokples. I impɔtant fɔ mɛzhɔ di dimɛnshɔn dɛn kɔrɛkt wan fɔ mek shɔ se dɛn fit am fayn fayn wan.

Di kwaliti ɛn di tɛm we di jig mashin go de fɔ lɔng tɛm na impɔtant tin dɛn bak fɔ tink bɔt. Fɔ put mɔni na wan ay kwaliti mashin impɔtant fɔ yuz fɔ lɔng tɛm ɛn fɔ wok fayn fayn wan. Di mashin fɔ mek frɔm strɔng tin dɛn we go ebul fɔ bia wit di rigors fɔ wok we gɛt ebi ebi wok. Apat frɔm dat, i fayn fɔ pik wan mashin frɔm wan manifakta we gɛt gud nem we de gi warranty ɛn afta-sɛl sɔpɔt. Dis de gi ashurant ɛn pis na yu maynd if ɛnitin apin tumara bambay.

Dɔn bak, dɛn nɔ fɔ fɔgɛt di izi we aw dɛn de yuz ɛn mentenɛns. Wan jig mashin we de yuz am we gɛt klia instrɔkshɔn ɛn kɔntrol dɛn we pɔsin kin ɔndastand kin sev tɛm ɛn tray we i de wok. Apat frɔm dat, fɔ mek dɛn kɔntinyu fɔ mek di mashin fayn ɔltɛm na impɔtant tin fɔ mek shɔ se di mashin go de fɔ lɔng tɛm. I impɔtant fɔ pik wan mashin we izi fɔ klin, savis, ɛn ripɛnt fɔ mek dɛn nɔ gɛt bɔku tɛm fɔ du di wok ɛn fɔ mek dɛn gɛt mɔ prɔdaktiviti.

Dɔn

Jig mashin na impɔtant tul fɔ minral prɔsesin ɔpreshɔn as dɛn kin separet valyu minral frɔm west matirial tru graviti separeshɔn. Dɛn kin yuz bɔku tin dɛn ɛn dɛn kin fɛn aplikeshɔn dɛn na difrɛn industri dɛn lɛk mayning, minral prɔsesin, risaykul, ɛn fɔ pripia kol. Jig mashin dɛn de gi efyushɔn ɛn ifɛktiv separeshɔn sɔlvishɔn dɛn bay we dɛn de yuz spɛshal graviti. Dɛn yus de ɛp fɔ mek di opareshɔn wok fayn fayn wan, i de ɛp fɔ mek dɛn kɔntinyu fɔ du tin dɛn we go kɔntinyu fɔ de, ɛn i de ɛp fɔ mek di envayrɔmɛnt kɔntinyu fɔ de.

Dɛn mashin ya de gi impɔtant bɛnifit dɛn, we inklud kɔst-ɛfɛktiv ɛn rilaybiliti, we de mek dɛn impɔtant fɔ ɔptimayz risɔs yutilizeshɔn ɛn ajɔst sakrifays na rispɛktiv industri dɛn. Bɔt fɔ pik di rayt jig mashin nid fɔ tek tɛm tink bɔt tin dɛn lɛk kapasiti, saiz, matirial tayp, kwaliti, ɛn izi fɔ yuz. Fɔ put mɔni na jig mashin we dɛn kin abop pan ɛn we go wok fayn kin mek di wok go bifo ɛn i kin ɛp fɔ mek di opareshɔn dɛn go bifo.