China chu khawvela bawlhhlawh paih chhuaktu ram lian ber pahnihna a ni ta a, China rama nitin mi pakhat bawlhhlawh siam chhuah chu China rama khawpui siam chhuah a nih avangin a rang em em a, hei hi a rang em em a, a chhan chu ram changkang zawkte nen pawh a sang ber a ni. China rama nitin nun bawlhhlawh paihna rate hi kum 2010 aṭang khan kum 2010 aṭang khan kum 2010 aṭang khan kum 2018 aṭang khan kum leh kum a pung chho zel a, kum 2019-a Ministry of Construction of China-in China rama Urban Construction-a a siam, kum 2010 aṭanga a lan dan chuan.

China ramah hian tun thlenga nitin bawlhhlawh paihna tur kawng harsa lo tak tak pathum a awm a, chungte chu Sanitary Landfill, Incineration leh a dangte a ni. Tun hnaiah China rama khawpui tinin nitin bawlhhlawh an paih vek tawh laiin sanitary landfill hman dan chu 60%, 35% leh midang tan 5%-in a khuh a ni. Chu chu China rama sanitary landfill hman dan chu a lar ber tihna a ni. Sanitary landfill hman dan chuan ram lian tawk a mamawh a, bawlhhlawh tamna leh bawlhhlawh tamna bakah bawlhhlawh tamna ram chhunga a inhnim pil theihna tur a nei a, he hmanrua hian hetiang harsatna hi a tuar thei tawh lo. Incineration kalphung chungchangah hian hlawkna engemaw zat a awm a, chu chu harmless, carbon reduction sang tak,ram tam zawk chhanhim leh power leh heating siam avanga extra profit siam te hi a ni. Chuvangin, bawlhhlawh hmanrua hman tangkai leh power siam chhuahna atana bawlhhlawh halna nasa taka tihhmasawn chu China chuan a tichak a ni.

Incineration hmanga bawlhhlawh paih dan hi boruak humhalh leh tunlai khawvel humhalh dan lar ber pawla ngaih a ni. Ram chhung leh ram pawn lama mithiamte chuan chu chu bawlhhlawh paih chhuahna kawng awmchhun a ni tih an chhut a ni.

Power siam chhuahna atana incineration hmanga slag lo chhuak chu slag, glass, ceramics, lung, etc. ang chi thil a ni a, a lan tam zawk hi porous, light gray sand leh lung nen a inang a ni. slag hi bawlhhlawh solid of waste material anga ngaih pawh a ni. Slag hmasawnna hi China leh renewable energy siam chhuah a nih bakah document of GB18485《 angin a fuih bawk a, chu chu nitin nunna bawlhhlawh paihna incineration pollution standard a ni

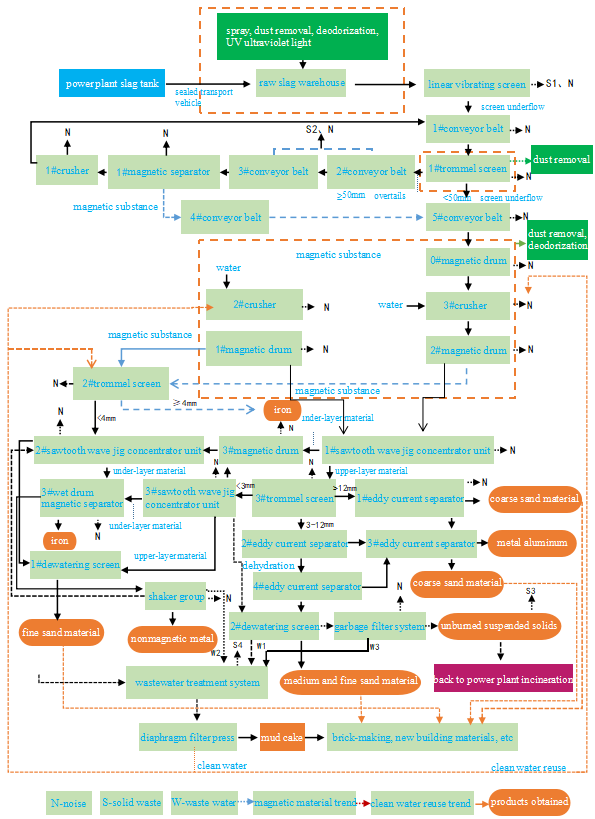

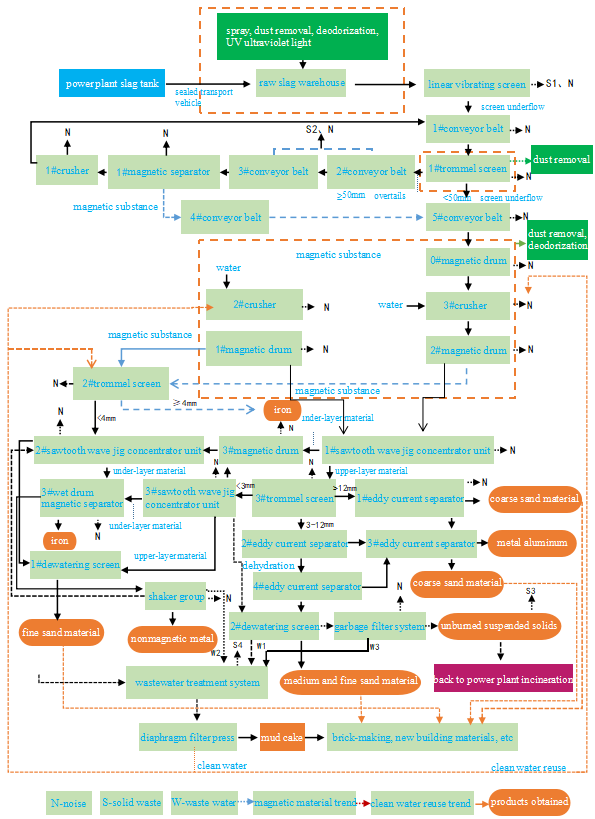

China sawrkar-in a pawm tawh environment humhalhna policy kalpui nan Ruijie Slag Equipment Manufacturing Ltd chuan slag disposing technology-a thil thar siam chhuah chu tihchangtlun leh tihchangtlun a siam a ni. Slag production line pum pui hmanrua te hian Slag Metal Resource Utilization Technology, Water Cycle Comprehensive Utilization Technology leh Slag Sand Making Resource Technology te chu a inzawm khawm a, chu chu slag resource hman dan kimchang taka hman a nih theih nan ram pum huap thil mamawh kaihhnawih a tlin theih nan leh industry-a hmahruaitu level-ah a awm a ni.

Ruijie Equipment hian nitin nun bawlhhlawh halna lam ngaihtuah thin company atanga sorting slags siam chhuah zawng zawng chu power generation angin a design thei a, clients mamawh te chunga sorting slags base recycling a siam thei bawk. Nitin bawlhhlawh halna slags chu a pumin recycled a ni ang a, resource hman dan chu chaw pek dan, screening, crushing, magnetic sorting, jigging, sand washing, sorting, dewatering, filter-press etc. te a ni ang.

Slag sorting siam dan tur:

Step 1:Feeding .

Hopper chhunga thil awmte chu reciprocating feeder-ah paih a ni ang a, forklift-a slag-te chu hopper-a dah hnuah next procedure atan convey belt-ah phurh luh a ni ang.

Step 2:Screening tih a ni.

Slag lian leh te, trommel screen hmanga slags te an sort hnuah particle te chu an siam chhuak ang.

Step 3:Crushing .

Slag-a particle te chu a te zawk a, crusher chhunga slags te chu metal a sorting rate tihsan nan an paih hnuah an crushing a.

Step 4:Jigging .

Minerals specific gravity hrang hrang nei thlan nan jigging separation atan ore leh gangue te specific gravity difference kan hmang a ni.

Step 5:Tui leh silfai .

Sand stone hman nawn leh tur chuan slags te chu chiang taka tihfai a ngai a, slags thianghlim zawk nan sand stone-a khuh bawlhhlawh te chu lakchhuah a ngai bawk.

Step 6:Sorting .

Chutiang metals slag-a mix te chu Eddy current separator hmangin an sort ang a, an recycle ang.

Step 7: Dewathering tih a ni.

Slags te hi tui leh sand inkarah dewatering screen hmangin an inthen ang a, chu chu sand leh tui recycle nan hman a nih theih nan a ni ang.

Step 8: Filter-Press 1000 a ni.

Filter hmanga sands dah tawhte chu filter a ngai a, chutih lai chuan tui thianghlim chu tui thianghlim tank chhungah cement cake lakchhuah leh chhuah tir turin a luang lut a ni.

Step 9:Tailings .

Slags te chu thliar hrang a, process a nih hnuah pawh environment friendly sand a nih hnuah kawngpui siamna hmanrua atan emaw, brick siam nan emaw hman theih a ni.

A tawpah chuan slag paih dan zawng zawng hian natural resource hmanga recycle tum tihhlawhtlinna atana 100% disposed a tichiang a ni.