Sho

Insay di kɔmpleks wɔl we dɛn de handle matirial, di efyushɔn ɛn rilaybiliti fɔ di ikwipmɛnt dɛn na di men tin. Indastri dɛm we de frɔm mayning to risaykul dipen bɔku pan mashin dɛm we kin ebul fɔ handle bɔku bɔku matirial wit prɛsishɔn ɛn kɔnsistɛns. Pan di bɔku bɔku divays dɛn we dɛn yuz, di . Reciprocating feeder stand out as wan impɔtant komponent fɔ mek shɔ se di opareshɔn dɛn go fayn fayn wan. Dis atikul delv insay di signifyans fɔ reciprocating feeders in matirial handling, exploring dɛn dizayn, funkshɔnaliti, ɛn di advantej dɛn we dɛn de briŋ to industrial prɔses.

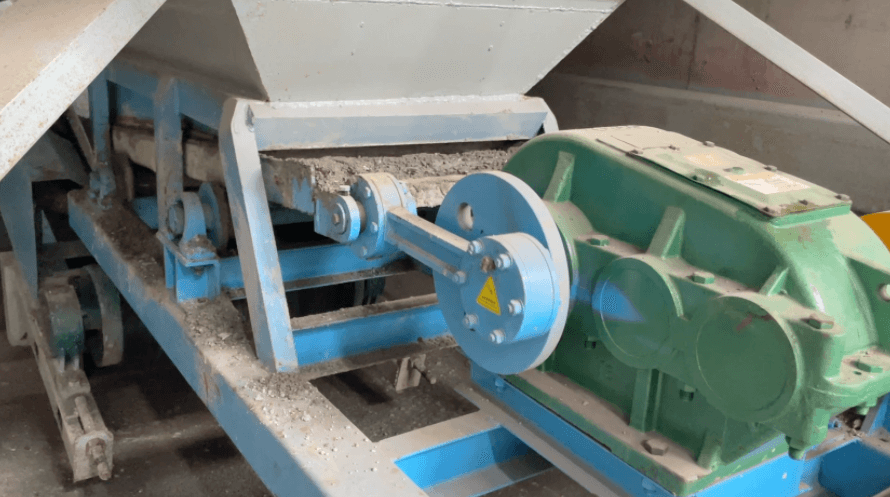

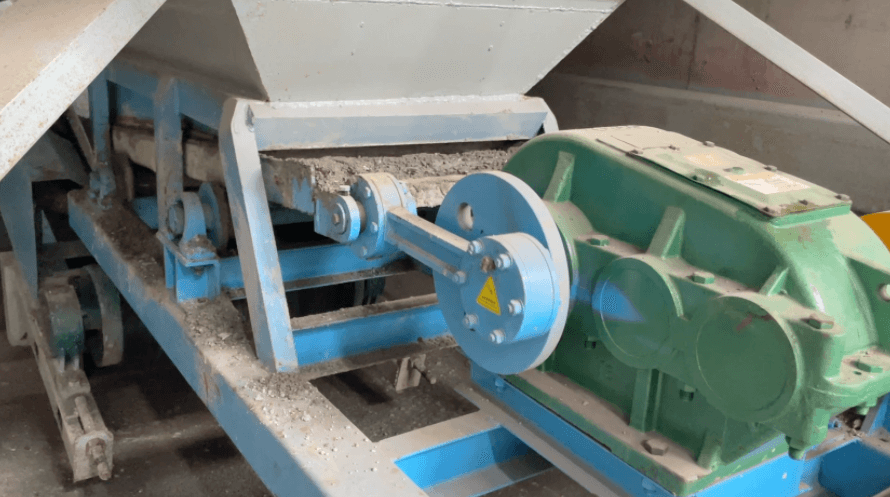

Risiprokayt fida na wan kayn mɛkanikal ikwipmɛnt we dɛn kin yuz fɔ kɔntrol di flɔ fɔ bɔlk matirial frɔm stɔrɔj saylɔs, hop, ɔ kɔnvayɔra to dɔŋstrim prɔses. I de wok pan wan simpul yet ifektiv mɛkanism, usay wan reciprocating plet de muv bak ɛn go fɔ fid matirial dɛn na wan kɔntrol rit. Di dizayn de mek shɔ se dɛn de dischaj wan kɔnsistɛns ɛn yunifom, we impɔtant fɔ mek dɛn kɔntinyu fɔ balans ɛn efyushɔn fɔ di wan ol matirial hanlin sistem.

Ki komponent ɛn dizayn ficha dɛn .

Di praymar komponent dɛm fɔ wan reciprocating feeder inklud di fida freym, reciprocating plet, drayv mɛkanizm, ɛn kɔntrol sistem. Di fida freym de gi strɔkchɔral sɔpɔt, we di reciprocating plet de muv ɔrizɔntal ɔ na inklin fɔ push matirial fɔ go bifo. Di drayv mɛkanizm, we bɔku tɛm kin gɛt pawa bay ilɛktrik mɔta, kin chenj rɔtin muvmɛnt to linya rɛsiprokɛt muvmɛnt. Advans fida dɛn kin inkɔrpɔret bak vayriɔbul spid drayv ɛn ɔtomɛshɔn kɔntrol fɔ ajɔst di fidin ret akɔdin to di prɔses rikwaymɛnt dɛn.

Di rol we reciprocating feeders de ple fɔ mek dɛn ebul fɔ handle matirial .

Reciprocating feeders de ple wan impɔtant rol na difrɛn stej dɛn fɔ matirial hanlin. Dɛn de mek shɔ se dɛn gɛt stedi sapɔt fɔ matirial to krɔsh, skrin, ɛn kɔnvayɔ, fɔ mek dɛn nɔ mek bɔtul-nɛk ɛn fɔ mek di ɔl prodaktiviti bɛtɛ. Bay we dɛn de gi wan kɔntrol fid rit, dɛn de ɛp fɔ minimiz wear ɛn tear pan daunstrim ikwipmɛnt, ridyus mentenɛns kɔst ɛn dawt tɛm.

Aplikeshɔn dɛn akɔdin to di industri dɛn .

Di versatility of reciprocating feeders de mek dɛn fit fɔ wan big rich industri. Insay mayning, dɛn de handle Ores ɛn Minerals, we de rigul di flɔ to prɔsesin plant dɛn. Insay kɔnstrɔkshɔn, dɛn de manej agregɛt dɛn lɛk san ɛn gravɛl. Di risaykul industri de yuz dɛn fɔ fid skrap matirial, we insay agrikalchɔral biznɛs, dɛn de handle gren ɛn ɔda bɔku bɔku komoditi dɛn. Dɛn ebul fɔ handle difrɛn matirial kayn dɛn, frɔm fayn fayn paoda to big big lumps, ɔndaskayn dɛn impɔtants insay matirial handlin sistem.

Advantej fɔ yuz reciprocating feeders .

Implimentin reciprocating feeders in material handling de gi sɔm bɛnifit dɛn we de ɛp fɔ mek di ɔpreshɔnal efyushɔn ɛn rilaybiliti go bifo.

Kɔnsistɛns matirial flɔ .

Wan pan di praymar advantej na di abiliti fɔ mentɛn wan kɔnsistɛns matirial flɔ. Di reciprocating motion de mek shɔ se dɛn de sheb di matirial dɛn ivin, we de ridyus di chans fɔ blok ɔ sɔj we kin ambɔg di dɔŋstrim prɔses.

Di ret fɔ it we dɛn kin ajɔst .

Reciprocating feeders alaw fɔ prɛsis kɔntrol oba fidin rit. Di wan dɛn we de wok kin ajɔst di spid ɛn di lɔng lɔng we fɔ mek dɛn mach di tin dɛn we dɛn nid fɔ du fɔ sɔm patikyula aplikeshɔn dɛn, we kin mek dɛn ebul fɔ du di wok fayn fayn wan ɛn yuz dɛn ɛnaji fayn fayn wan.

Durability ɛn lɔw mentenɛns .

Dɛn bil am fɔ handle ebi ebi lod ɛn abrasive matirial, reciprocating feeders na pipul dɛn sabi fɔ dɛn robust kɔnstrɔkshɔn ɛn fɔ de te. Dɛn simpul dizayn kin rili mek di pat dɛn we de muv nɔ bɔku, dɛn kin translet to di nid we dɛn nid fɔ mek dɛn mentenɛns ɛn lɔng savis layf.

Kes Stɔdi: Risiprokɛt fida dɛn we de wok insay akshɔn .

Fɔ sho di impak we di reciprocating feeders gɛt, tink bɔt aw dɛn de impruv dɛn na wan mayning ɔpreshɔn. Wan mayning kɔmni bin gɛt prɔblɛm dɛn wit di tin dɛn we dɛn nɔ bin ebul fɔ sheb, ɛn dis bin mek dɛn nɔ ebul fɔ du di rayt tɛm ɔltɛm. bay we dɛn de intagret wan . Reciprocating feeder insay dɛn sistɛm, dɛn bin ajɔst wan stebul fid rit, ridyus di ikwipmɛnt strɛs, ɛn inkrid thruput bay 15%.

Insay wan ɔda ɛgzampul, wan risaykul fasiliti we de dil wit miks skrap matirial dɛn bin nid fɔ gɛt sɔlv fɔ mek dɛn nɔ klog insay dɛn prɔsesin ikwipmɛnt. Di reciprocating feeder bin gi wan kɔntrol ɛn ivin fid, we mek di fasiliti ebul fɔ wok kɔntinyu wit smɔl intarapshɔn.

Integreshɔn wit ɔda matirial hanlin ikwipmɛnt dɛn .

Bɔku tɛm, di fida dɛn we de gi it kin bi pat pan wan big matirial we de handle ɛkosistim. Dɛn kin wok fayn fayn wan wit krɔsh, skrin, kɔnvayɔ, ɛn sɛpareta. fɔ ɛgzampul, we dɛn pe am wit wan Magnɛtik sɛpareta , dɛn de mek shɔ se dɛn de kɔntinyu fɔ flɔ di matirial dɛn, ɛn dɛn de ɛp fɔ mek di separeshɔn efyushɔn fɔ di fɛro mɛtal dɛn frɔm di bɔlk matirial.

Kastomayshɔn ɛn Skalabiliti .

Di wan dɛn we de mek di tin dɛn kin gi reciprocating feeders insay difrɛn saiz ɛn kɔnfigyushɔn fɔ mit spɛshal industri nid dɛn. Ilɛksɛf na fɔ handle fayn patikyula ɔ big, ebi matirial, dɛn fida ya kin kɔstɔmayz fɔ kapasiti, fidin rit, ɛn strɔkchɔral dizayn. Dis skɛlabiliti de mek dɛn fit fɔ smɔl ɔpreshɔn ɛn bak big industrial plant dɛn.

Teknɔlɔji advansmɛnt dɛn fɔ rɛsiprokɛt fida dɛn .

Di advansmɛnt dɛn we dɛn dɔn mek pan tɛknɔlɔji dɔn mek dɛn mek mɔ sofistikiet rɛsiprokɛt fida dɛn. Di mɔdan fida dɛn kin gɛt tin dɛn lɛk ɔtomɛshɔn, rimot monitarin, ɛn intagreshɔn wit plant kɔntrol sistem dɛn. Dɛn ɛnhansmɛnt ya de ɛp fɔ mek di opareshɔn wok fayn, we de alaw fɔ mek dɛn ajɔst di rial tɛm ɛn di prɛdiktiv mentenɛns.

Energy efficiency .

Enaji kɔnsɔmshɔn na impɔtant kɔnsidareshɔn insay matirial hanlin ɔpreshɔn. Nyu reciprocating feeders dɛn dɔn disayn wit motoka ɛn drayv dɛn we nɔ de yuz bɔku ɛnaji, we de ridyus di opareshɔnal kɔst ɛn di envayrɔmɛnt impak. Variable frikshɔn drayv (VFD) alaw fɔ prɛsis kɔntrol fɔ moto spid, optimizing ɛnaji yuz akɔdin to dimand.

Di tin dɛn we yu fɔ tink bɔt fɔ mek yu nɔ gɛt prɔblɛm .

Sef na di men tin we impɔtant pas ɔl na di say dɛn we dɛn de mek industri. Reciprocating feeders kin kɔntribyut to wan wokples we sef bay we dɛn de minimiz di nid fɔ manual intervention in matirial handling. Di tin dɛn lɛk dizayn dɛn we dɛn lɔk kin mek di wokman dɛn nɔ bɔn ɛn dɛn kin protɛkt di wokman dɛn fɔ mek di pat dɛn nɔ muv. Rigyul mentenɛns ɛn adherence to sefty protɔkol impɔtant fɔ mek shɔ se dɛn fida dɛn ya de wok fayn fayn wan.

Mentɛnans ɛn Trabulshut .

Wail reciprocating feeders dem sabi dem fo dem durability, regular maintenance na nesiseri fo sustain optimal pefomans. Mentɛnans aktiviti dɛn na fɔ inspɛkt wɛr pat dɛn, lɔbrikeshɔn fɔ di kɔmpɔnɛnt dɛn we de muv, ɛn chɛk alaynɛshɔn. Fɔ no di tin dɛn we de apin kwik kwik wan lɛk nɔys we nɔ kɔmɔn ɔ vaybreshɔn kin mek dɛn nɔ gɛt bɔku mɔni fɔ brok.

Kɔmɔn chalenj ɛn sɔlv dɛn .

Kɔmɔn chalenj dɛn wit rɛsiprokɛt fida dɛn na matirial bildup, kɔmpɔnɛnt wear, ɛn mɛkanikal fayl. Sɔlv dɛn kin involv fɔ impruv di rutin klin schedule, yuz tin dɛn we nɔ de west fɔ ay-kɔntakt eria dɛn, ɛn mek shɔ se di drayv mɛkanism de fayn fayn wan. Fɔ de proaktiv wit mentenɛns de ɛp fɔ ɛkstɛnd di fida in layfspan ɛn fɔ mek i kɔntinyu fɔ wok fayn fayn wan.

Envayrɔmɛnt impak ɛn sastaynabiliti .

Insay di industrial land skay tide, sastaynabiliti na wan impɔtant tin we de mɔna pipul dɛn. Risiprokɛt fida dɛn kin ɛp fɔ mek di envayrɔmɛnt nɔ apin fayn fayn wan bay we dɛn de ridyus di west ɛn ɛnaji we dɛn de yuz. Dɛn prɛsishɔn insay matirial handlin de minimiz ɔvafid ɛn spilaj, we kin mek dɛn west di risɔs ɛn di envayrɔmɛnt kɔntaminɛshɔn.

Risayklin ɛn Rishɔs Rikɔvayshɔn .

Insay risaykul aplikeshɔn, rɛsiprokɛt fida dɛn de mek dɛn ebul fɔ prosɛs di west matirial dɛn fayn fayn wan, we de mek am izi fɔ mek dɛn gɛt bak valyu tin dɛn. Bay we dɛn mek shɔ se dɛn gɛt kɔnsistɛns fid fɔ sɔt ɛn prosɛs ikwipmɛnt, dɛn de ɛp fɔ mek di risaykul opareshɔn dɛn wok fayn, dɛn de ɛp fɔ kɔnsavayshɔn fɔ di risɔs ɛn fɔ ridyus di west.

Selekt di rayt reciprocating feeder .

Fɔ pik di rayt we fɔ rɛsiprokɛt fida, yu nid fɔ tek tɛm tink bɔt difrɛn tin dɛn, lɛk di tin dɛn we yu nid fɔ du, di tin dɛn we yu nid fɔ du, ɛn di kɔndishɔn dɛn we yu fɔ wok. Fakta dɛm lɛk matirial density, abrasiveness, moisture content, ɛn patikyula saiz de inflɔws di fida in dizayn ɛn spɛsifikɛshɔn dɛm.

Fɔ tɔk wit pipul dɛn we sabi bɔt dis .

Fɔ ɛnjɔy wit manifakta ɛn injinia dɛn we spɛshal pan matirial hanlin ikwipmɛnt impɔtant. Dɛn kin gi insayt fɔ di bɛst fida kɔnfigyushɔn fɔ spɛshal aplikeshɔn dɛn. Kɔmni dɛn lɛk Ruijie de gi wan rich reciprocating feeders ɛn dɛn kin ɛp fɔ kɔstɔmayz sɔlvishɔn fɔ mit yunik ɔpreshɔnal nid dɛn.

Di tin dɛn we go apin tumara bambay we dɛn de yuz matirial fɔ handle .

Di matirial hanlin industri de evolv wit advansmɛnt in teknɔlɔji ɛn shiftin industri dimand. Ɔtomɛshɔn, Intanɛt ɔf Tin dɛn (IoT), ɛn data analitiks de chenj aw matirial hanlin ikwipmɛnt de wok. Dɛn de op se reciprocating feeders go intagret mɔ smat teknɔlɔji dɛn, we go alaw fɔ mek dɛn ebul fɔ wach di tin dɛn we dɛn dɔn mek, fɔ mek dɛn ebul fɔ du mɔ, ɛn fɔ mek dɛn ebul fɔ wok fayn fayn wan.

Emphasis pan ɔtomɛshɔn ɛn kɔnɛktiviti .

Ɔtomɛshɔn de ridyus di rilayns pan manual leba ɛn i de inkrisayz sefty. Reciprocating fida dɛn we gɛt sɛns ɛn kɔnɛktiviti kin transmit ɔpreshɔnal data fɔ analisis. Dis data kin yuz fɔ optimize pefɔmans, schedule mentenɛns, ɛn ridyus dawt tɛm.

Dɔn

Di Reciprocating feeder na undeniably wan impɔtant komponent insay matirial handlin sistem akɔs difrɛn industri dɛm. I ebul fɔ gi kɔnsistɛns, kɔntrol fidin de ɛp fɔ mek di opareshɔn wok fayn, i de ridyus di ikwipmɛnt dɛn we de west, ɛn i de ɛp fɔ mek di say dɛn we dɛn de wok sef. As di industri dɛn de kɔntinyu fɔ luk fɔ impɔtant improvements in prodaktiviti ɛn sastaynabiliti, di reciprocating fida go stil bi wan impɔtant tul, adapt wit teknɔlɔjik advansmɛnt fɔ mit di fiuja chalenj dɛn.

We dɛn ɔndastand aw i de wok, di bɛnifit dɛn we i de du, ɛn di we aw i de yuz am, di biznɛs dɛn kin disayd fɔ du sɔntin we dɛn no we dɛn de put di wan dɛn we de gi it to ɔda pipul dɛn we de gi dɛn tin fɔ it insay dɛn opareshɔn. Fɔ embras dis rilibul teknɔlɔji kin mek dɛn impɔtant impɔtant improvement dɛn na di matirial hanlin prɔses, pozishɔn kɔmni dɛn fɔ sakrifays insay wan wɔl we de kɔmpit ɛn we de tink bɔt tin dɛn we de apin mɔ ɛn mɔ.