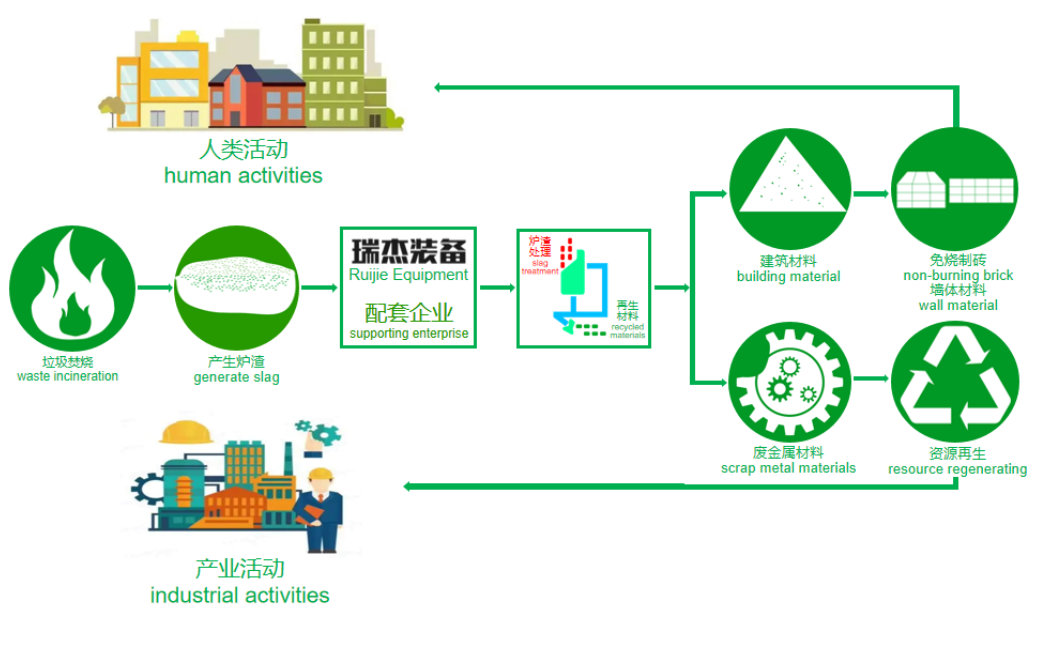

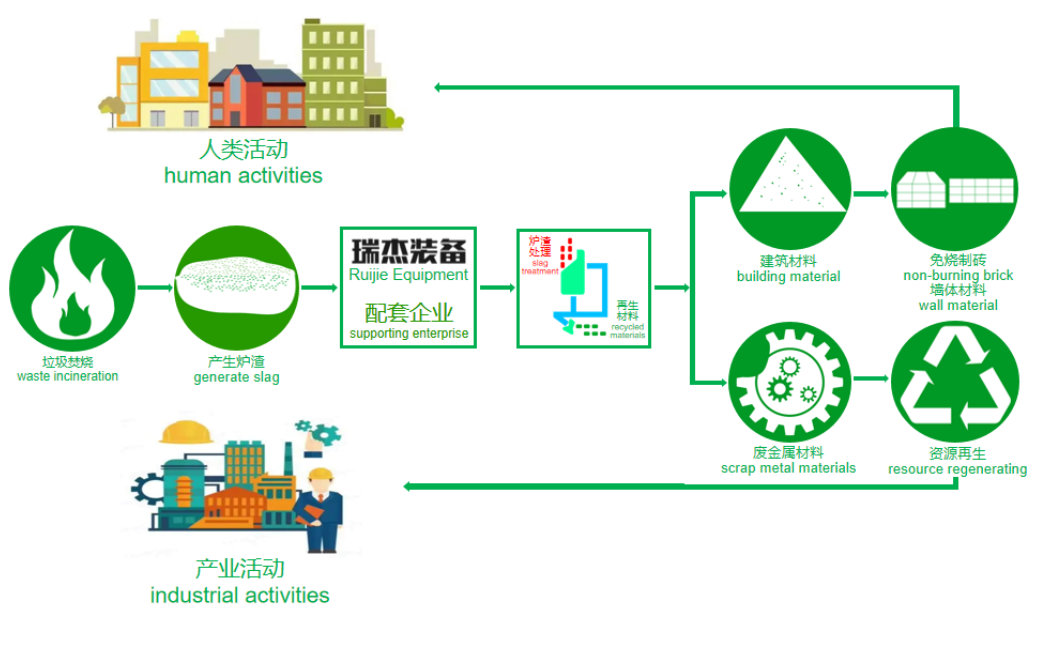

Domestic waste incineration power siamna atanga slag siam chhuah ber chu slag, glass, ceramics, lung, etc. te an ni a, a tam zawk chu porous leh light gray sand grain ang chi an ni.

Slag hi solid waste ni mah se, renewable resource a ni a, hmasawnna thlawptu leh nasa taka fuihtu a ni a, chu chu GB18485 'Pollution Control Standards for Domestic Waste Incineration'-in a tih angin a ni.

Slag enkawlna kalphung thar hian resources hmanna atan hlutna thar a siam a ni .

Slag hmanga enkawlna hian ash leh slag component-te physical property inang lo tak takte chu screening, crushing, impurity removal, magnetic separation, non-ferrous metal separation, precious metal separation, tailings recovery, waste water treatment leh resource process dangte, iron, copper, Zinc leh metal hlu tak tak dangte recovery neih theihna turin a hmang ber a ni. Slag sort hnuah recycled block siam a ni a, sand siam zawh tawh chu roadbed leh bottom aggregate atan hman theih a ni.

Process flow: 1.1.

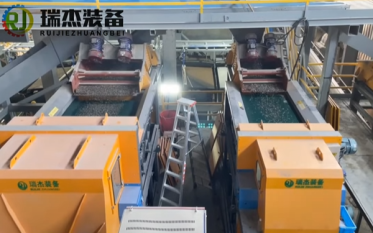

Kan company hian slag chu bawlhhlawh incineration power plant atanga physical methods (particle size screening, magnetic separation, buoyancy separation leh eddy current separation te pawh a huam tel) atanga a reprocess ber a, iron, metal aluminum leh non-magnetic metals (metal copper, etc.) tlem te te a then hrang a, construction sand (coarse, medium, leh fine sand) te pawh a hun laia hmuh theih a ni.

Sorted metal materials te hi recycling unit te hnenah hman nawn leh theih turin an hralh thin a; Coarse, medium leh fine sand materials te hi brick siam emaw, hman nawn leh emaw atan material production plant siamin an hmang thin. Specific production process flow leh pollution production process diagram chu figure-ah hian tarlan a ni:

Chaw pek dan: Forklift truck hmanga loading .

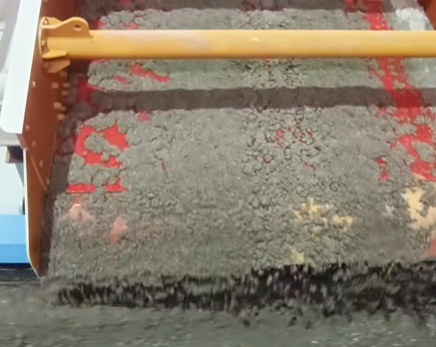

sieving: a . Trommel screen equipment hmang hian slag chu coarse slag leh medium slag-ah then a ni a, hei hi circular magnetic separation leh crushing step dang atan a awlsam hle.

Trommel screen hmang hian jigging material chu coarse material leh fine material-ah then a ni a, hei hi a hnuaia step-a circulating vortex hmanga coarse material thliar hran leh crush-na atan a remchang a, copper leh aluminum sorting rate pawh a tha zawk.

Crushing: a . Slag crusher hi slag step khat hnu step khata particle size tihtlem nan hman a ni a, tihtlem leh crush a ni a, chutiang chuan metal sorting rate tihsan nan Blacksmiths hi iron slag mixture te tihchhiat leh theh darh nan an hmang thin.

Magnetic separation : Slag chhunga thir slag mixture chu a hmin theih nan a inthen a; Slag chhunga thir block leh iron powder te chu recycle theih turin an inthen a.

eddy current sorting: Eddy current separator hmang hian slag chhunga aluminum metal chu sort leh recover nan hman a ni.

Gravity s orting : Copper metal sort leh recover nan jig leh shaker hmangin.

Magnetic separator awm reng tur : .Permanent magnetic separator hian permanent magnet a nei a, chu chuan magnetic field chak tak a siam a, chu chuan thil chi hrang hrang atanga ferrous contaminants te hip leh man theihna a siam a ni. Iron chu thil dang atanga a then hran theih nan a tha zawngin a then thei a, chu chuan high purity iron recovery a thlen thei a ni.

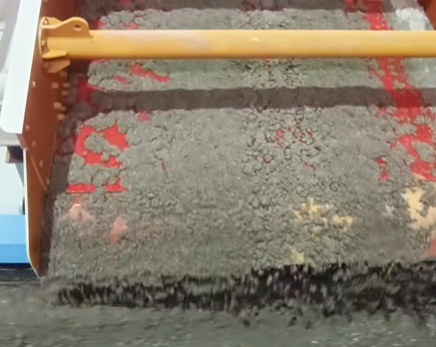

Sand Washing: Impeller rotation hnuaiah chuan a thil siam chu a tifai a, chu chuan sand leh gravel chunglam khuh tu bawlhhlawh te chu a paih chhuak a, a tihfai na machine chu tui tlakchham vek a ni a, chu chuan a thil siam powder awm zat chu a ti tlem thei hle a ni.

Dewatering: Metal inthen tawh chu vibrating hmangin dehydrated a ni . Dewatering screen a ni a ; Dewatering screen hian tui leh sand a then a, dehydration hnua thil siam zawh tawha tui awm zat a hniam bawk.

Tawpna

Product chu enkawl a nih hnuah, resource hman dan chu a takin a thleng a, boruak tichhe lo (environment friendly sand) chu kawngpui paving material atan direct-in hman a ni a, boruak tichhe lo brick leh cement concrete-ah te pawh siam theih a ni a, chu chuan bawlhhlawh chu thil hluah a chantir thei a ni Sorted metal substances te hi metal processing plant-a metal product-ah te process theih a ni.